In recent years, the manufacturing landscape has undergone a profound transformation, heavily influenced by advancements in laser and CNC machine technologies. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach USD 100 billion by 2025, growing at a CAGR of 6.1%. This growth is complemented by the increasing adoption of laser technology across various sectors, with the laser cutting market projected to hit USD 6.6 billion by the same year. The integration of these technologies into precision manufacturing not only enhances efficiency but also significantly improves the accuracy of production processes.

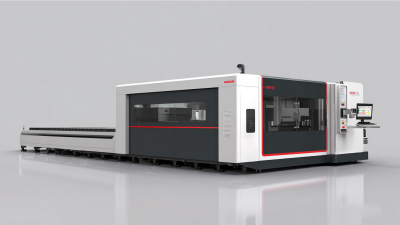

As industries move towards automation and smart manufacturing, the relevance of laser and CNC machines cannot be overstated. They provide unmatched capabilities in cutting, engraving, and milling, redefining quality standards and operational productivity. With the rise in demand for custom and complex parts, the precision offered by laser and CNC machines provides a competitive edge that many manufacturers are keen to leverage. This article outlines the top five laser and CNC machines set to revolutionize precision manufacturing by 2025, exploring their features, applications, and the impact they will have on the future of the industry.

In 2025, the landscape of precision manufacturing is dramatically changing thanks to advanced laser and CNC machines equipped with cutting-edge technology. One of the standout features of this year's leading laser machines is the integration of AI-driven process optimization. These machines can analyze cutting patterns and adjust parameters in real-time, ensuring optimal efficiency and precision in every project. This evolution not only enhances productivity but also significantly reduces material waste.

Moreover, enhanced connectivity features are another hallmark of 2025's laser machines. With IoT integration, manufacturers can now monitor performance and receive alerts remotely, allowing for proactive maintenance and fewer downtimes. This connectivity ensures that teams can maintain high levels of accuracy and efficiency no matter where they are operating from.

Tips: When investing in advanced laser machines, consider the level of AI and connectivity features that align with your production needs. Ensure proper training for your team to make the most out of these innovative tools. Regularly update software to take advantage of the latest features and improvements in precision crafting.

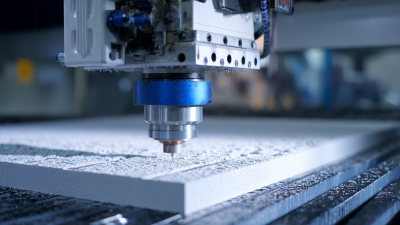

The advancements in CNC technology are set to significantly enhance manufacturing efficiency by 2025. According to market projections, the global metal forming tools market is expected to grow from $29.41 billion in 2025 to $51.67 billion by 2032, reflecting a compound annual growth rate (CAGR) of 8.4%. This growth is driven by increasing demand for precision manufacturing processes, which rely heavily on CNC machine capabilities. Specifically, the market for CNC machining centers alone is projected to increase from $2.45 billion in 2022 to $3.98 billion by 2030, achieving a CAGR of 6.5% during the period.

Moreover, the desktop CNC machine market is also poised for remarkable growth, expected to rise from $2.4 billion in 2024 to $6 billion by the end of 2037, with a CAGR of 9.5%. Such growth underscores the importance of CNC technology in producing high-quality, precise components across various industries. Additionally, the CNC machining center market is estimated to reach approximately $14.35 billion in 2025 and expand to $21.69 billion by 2033, with a 5.7% growth rate. These figures illustrate how advancements in CNC technology not only improve manufacturing efficiency but also drive the larger market forward, emphasizing the critical role of automation and precision in modern manufacturing practices.

The evolution of CNC machines has drastically transformed precision manufacturing, particularly when comparing traditional models to modern alternatives. According to a report by Allied Market Research, the global CNC machine market is expected to reach over $100 billion by 2025, highlighting the growing dependence on these advanced technologies in various industries. Traditional CNC machines typically rely on manual programming and limited operational capabilities, which restrict their efficiency and accuracy. These machines often experience downtime due to mechanical failures, leading to significant costs.

In contrast, modern CNC machines employ advanced algorithms, automated systems, and adaptive control technology to enhance precision and reduce operational risks. Research shows that integrating smart manufacturing techniques can lead to improvements in productivity by up to 30%. Modern machines also incorporate real-time monitoring and predictive maintenance features, ensuring that they operate at optimal levels with minimal interruptions. The shift from traditional to modern CNC machines represents not only a transition in technology but also a fundamental change in how precision tasks are approached, allowing manufacturers to meet evolving market demands more effectively.

The landscape of manufacturing in 2025 is increasingly being shaped by advancements in laser and CNC technologies. As industries strive for greater efficiency and precision, the integration of these high-tech solutions has become paramount. Laser machines, in particular, are revolutionizing processes by offering unparalleled accuracy in cutting and engraving, making them indispensable in sectors such as aerospace, automotive, and electronics. This precision not only enhances product quality but also significantly reduces waste, translating to more cost-effective production methods.

Moreover, the rise of digital manufacturing technologies is accelerating productivity across various domains. With the ability to automate and optimize workflows, CNC machines equipped with laser capabilities are providing manufacturers with the tools needed to adapt swiftly to changing market demands. As we look toward 2030, the laser processing market is projected to expand substantially, underscoring the importance of these technologies in driving innovation and competitiveness in the manufacturing sector. The trend signals a move toward more sophisticated, automated solutions that empower businesses to meet the challenges of modern production head-on.

This chart highlights the projected market growth for the top 5 laser and CNC machines that are set to revolutionize precision manufacturing by 2025. Each type of machine is expected to contribute significantly to the overall advancement in manufacturing processes.

The landscape of precision manufacturing is undergoing a transformative shift in 2025, driven by advancements in CNC and laser technologies. The global CNC machine market is projected to grow at a compound annual growth rate (CAGR) of 5.5%, reflecting the increasing demand for automated solutions across various sectors. Key industries such as automotive, aerospace, and electronics are particularly benefiting from this trend, leveraging CNC machines for enhanced accuracy and efficiency in production processes.

In parallel, the sheet metal processing equipment market is expected to expand significantly, growing from $35.51 billion in 2025 to an impressive $61.78 billion by 2032. This growth, exhibiting a robust CAGR, highlights the rising importance of laser cutting and machining technologies in the manufacturing environment. As industries continue to seek out precision and productivity, the integration of advanced CNC and laser systems is not just an innovation, but a necessity for maintaining competitive advantage in the evolving market landscape.