In the rapidly advancing field of precision engineering, the integration of technology is crucial for achieving high levels of accuracy and efficiency. One of the most transformative tools in this domain is the laser CNC machine. Renowned for its precision and versatility, the laser CNC machine has become an indispensable asset for engineers and manufacturers alike. As industries evolve, so do the demands for intricate designs and flawless execution, and the laser CNC machine stands out by offering unparalleled performance in these areas.

The benefits of utilizing laser CNC machines extend far beyond mere speed and accuracy. These advanced machines facilitate complex cuts and engravings that were once deemed impossible, making them a game-changer for diverse engineering projects. Furthermore, their ability to work with a wide array of materials, including metals, plastics, and wood, enhances their appeal in various applications. In this article, we will explore the top ten benefits of laser CNC machines for precision engineering projects, highlighting how they not only streamline production processes but also contribute to innovation and creativity within the industry. By understanding the advantages of this technology, professionals can better leverage its capabilities to meet the challenges of modern engineering.

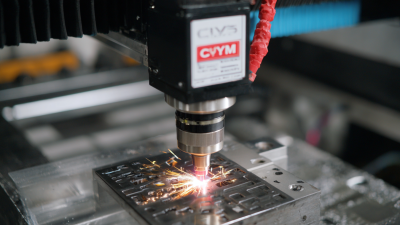

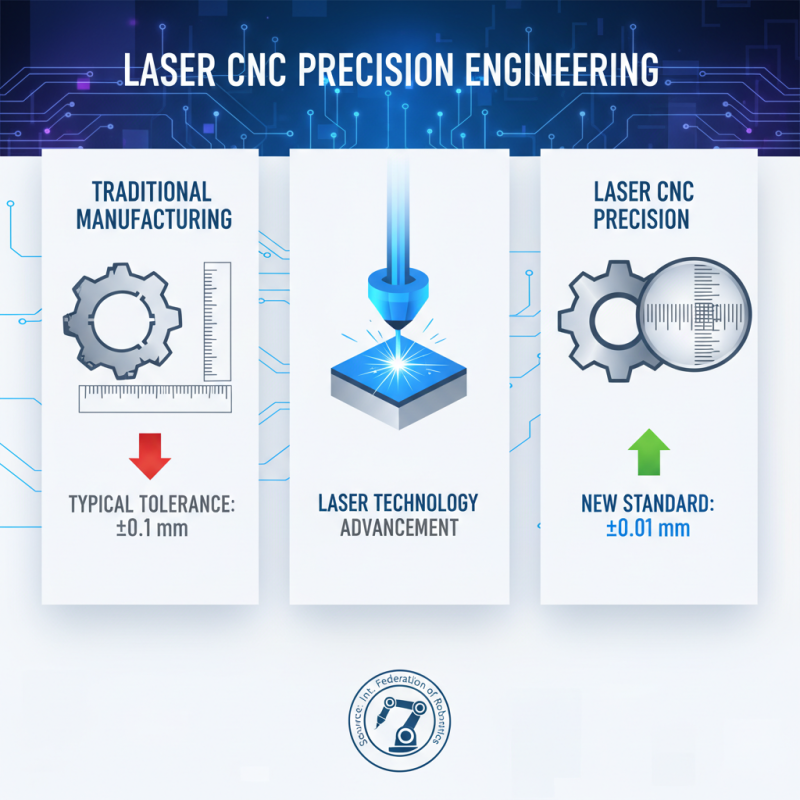

Laser CNC machines have revolutionized precision engineering, offering numerous advantages that enhance manufacturing capabilities. One significant benefit is the remarkable accuracy these machines provide. According to a report by the International Journal of Advanced Manufacturing Technology, laser-cut components can achieve tolerance levels as tight as ±0.01 mm, which is crucial for industries like aerospace and medical device manufacturing where precision is non-negotiable. This high level of precision minimizes material wastage and reduces the need for extensive post-processing, ultimately saving production costs.

Another notable advantage of laser CNC machines is their versatility. They can work with a variety of materials, including metals, plastics, and composites, making them suitable for diverse engineering applications. A study by Research and Markets estimates that the global laser cutting machine market will grow at a CAGR of 7.5% from 2023 to 2028, driven by the increasing demand for customized and intricate designs in sectors such as automotive and electronics. This adaptability allows manufacturers to respond quickly to changing market demands and tailor solutions to specific project needs, thereby enhancing overall operational efficiency.

Laser CNC machines have revolutionized precision engineering, offering remarkable enhancements in accuracy and precision during manufacturing processes. According to a report by the International Federation of Robotics, laser technology has advanced to provide tolerances as tight as ±0.01 mm, which significantly outperforms traditional manufacturing techniques. This level of precision allows engineers to produce intricate designs and components that meet strict industry standards, reducing the risk of errors and the need for costly rework.

In addition to accuracy, laser CNC machines provide exceptional repeatability, which is critical in large-scale production environments. Data from the American Society of Mechanical Engineers indicates that laser machining can achieve repeatability rates of 98% or higher. This consistency not only streamlines production workflows but also supports quality control measures, ensuring that every component produced is virtually identical. Moreover, the capability to precisely manipulate materials such as metals, plastics, and composites without introducing mechanical stress further enhances the overall integrity of the finished product. As a result, industries ranging from aerospace to medical device manufacturing are increasingly adopting laser CNC technology to optimize their engineering projects and achieve superior results.

Laser CNC machines have revolutionized precision engineering projects by significantly increasing efficiency and productivity in various operations. According to a report by the International Federation of Robotics, the adoption of laser cutting technology can increase manufacturing speed by up to 40%, minimizing downtime and streamlining production workflows. This efficiency is primarily due to the machines' ability to perform complex cuts with high precision in a fraction of the time taken by traditional machining methods. Consequently, businesses can enhance output without compromising quality, ultimately leading to higher profitability.

Furthermore, laser CNC machines are noted for their versatility and reduced setup times. Research from the Society of Manufacturing Engineers indicates that companies utilizing laser CNC technology experience a 25% reduction in setup time compared to conventional machining processes. This allows for more agile manufacturing practices, enabling quick adaptations to changing customer demands and market trends. As businesses move towards just-in-time production models, the speed and precision of laser CNC machines become critical in maintaining competitiveness in the ever-evolving landscape of precision engineering.

Laser CNC machines have revolutionized precision engineering by offering unmatched versatility in material processing and customization. These machines’re designed to handle a wide array of materials, ranging from metals like steel and aluminum to non-metals such as wood, plastics, and glass. According to a recent report by MarketsandMarkets, the global laser processing market is projected to reach $5.68 billion by 2025, showcasing the growing demand for such technology across various industries. This versatility allows precision engineers to seamlessly transition between different projects without the need for multiple machines, optimizing workflow and reducing overhead costs.

The customization capabilities of laser CNC machines further enhance their appeal in precision engineering. With advanced software integration, engineers can create highly intricate designs with remarkable accuracy, often down to the micrometer. A survey conducted by SME (Society of Manufacturing Engineers) found that 72% of respondents find customization options to be significantly improved when using laser CNC technology compared to conventional methods. This ability to adapt and refine designs quickly not only accelerates the prototyping process but also enhances overall product development timelines, leading to more innovative solutions tailored to specific client needs. As industries continue to push for efficiency and precision, the role of laser CNC machines in material processing remains essential.

| Benefit | Description | Material Compatibility | Ideal Applications |

|---|---|---|---|

| Precision Cutting | Laser CNC machines provide high precision cuts with minimal tolerance levels. | Metals, Plastics, Wood | Aerospace, Automotive, Furniture |

| Versatility | Suitable for a variety of materials and applications, allowing for customized solutions. | Glass, Fabric, Leather | Signage, Apparel, Crafting |

| Speed | Laser cutting processes are faster compared to traditional cutting methods. | Metals, Plastics | Mass Production, Prototyping |

| Low Material Waste | High precision minimizes waste material and optimizes costs. | All compatible materials | Sustainable Manufacturing |

| Complex Designs | Ability to create intricate designs that are difficult to achieve with traditional methods. | Metals, Wood, Plastics | Jewelry, Complex Machinery Parts |

| Automation and Integration | Easily integrates with CAD software and automation systems. | Various Materials | Automated Manufacturing Lines |

| Environmental Impact | Laser cutting produces fewer pollutants and better energy efficiency. | All compatible materials | Eco-friendly Projects |

| Customization | Enables tailored solutions for specific engineering needs. | Metals, Plastics, Wood | Custom Parts Manufacturing |

| User-Friendly Operation | Modern controls and interfaces make laser CNC machines easy to operate. | Various Materials | General Manufacturing |

| Safety Features | Built-in safety mechanisms ensure safe operation while cutting. | Compatible Materials | Industrial Applications |

Laser CNC machines have revolutionized precision engineering projects, particularly in terms of reducing waste and resource utilization during the production process. Traditional manufacturing methods often lead to significant amounts of scrap material due to their subtractive nature. In contrast, laser CNC technology employs a highly focused beam of light to cut through materials with exceptional accuracy, minimizing excess waste. According to a report by the International Journal of Advanced Manufacturing Technology, laser cutting processes can reduce material waste by as much as 30%, leading to improved efficiency and cost savings for manufacturers.

Moreover, the precision of laser CNC machines contributes to optimal resource utilization. With their ability to make intricate cuts and complex shapes without compromising the structural integrity of the materials, these machines allow engineers to use less raw material while still meeting design specifications. A study conducted by the American Society of Mechanical Engineers noted that laser machining processes could improve yield rates by as much as 15%, translating to reduced costs and a lower environmental footprint. As industries increasingly aim for sustainability, the adoption of laser CNC technology is becoming a critical aspect of production strategies, enabling companies to align their operations with eco-friendly practices while delivering high-quality products.