In the rapidly evolving landscape of manufacturing, CNC milling stands out as a cornerstone for precision and efficiency. As businesses increasingly seek to enhance their production capabilities, understanding how to unlock the full potential of CNC milling is paramount. This blog aims to provide a comprehensive guide to finding high-quality suppliers and optimal specifications for CNC milling. Whether you are a seasoned engineer or a newcomer to the field, mastering the nuances of CNC milling can lead to improved product quality and operational effectiveness.

Dive into our ultimate guide, where we will explore key factors to consider when selecting a supplier, essential specifications for CNC milling operations, and best practices for maximizing performance. By the end, you will be equipped with the knowledge to navigate this complex domain confidently, ensuring that your CNC milling projects exceed expectations.

CNC milling is a pivotal process in modern manufacturing, enabling precision machining across various industries. According to a report by Grand View Research, the global CNC machine market is projected to reach $100 billion by 2025, highlighting the increasing reliance on these advanced technologies. CNC (Computer Numerical Control) milling transforms raw materials into intricate parts with exact specifications, making it essential for industries such as aerospace, automotive, and healthcare.

CNC milling is a pivotal process in modern manufacturing, enabling precision machining across various industries. According to a report by Grand View Research, the global CNC machine market is projected to reach $100 billion by 2025, highlighting the increasing reliance on these advanced technologies. CNC (Computer Numerical Control) milling transforms raw materials into intricate parts with exact specifications, making it essential for industries such as aerospace, automotive, and healthcare.

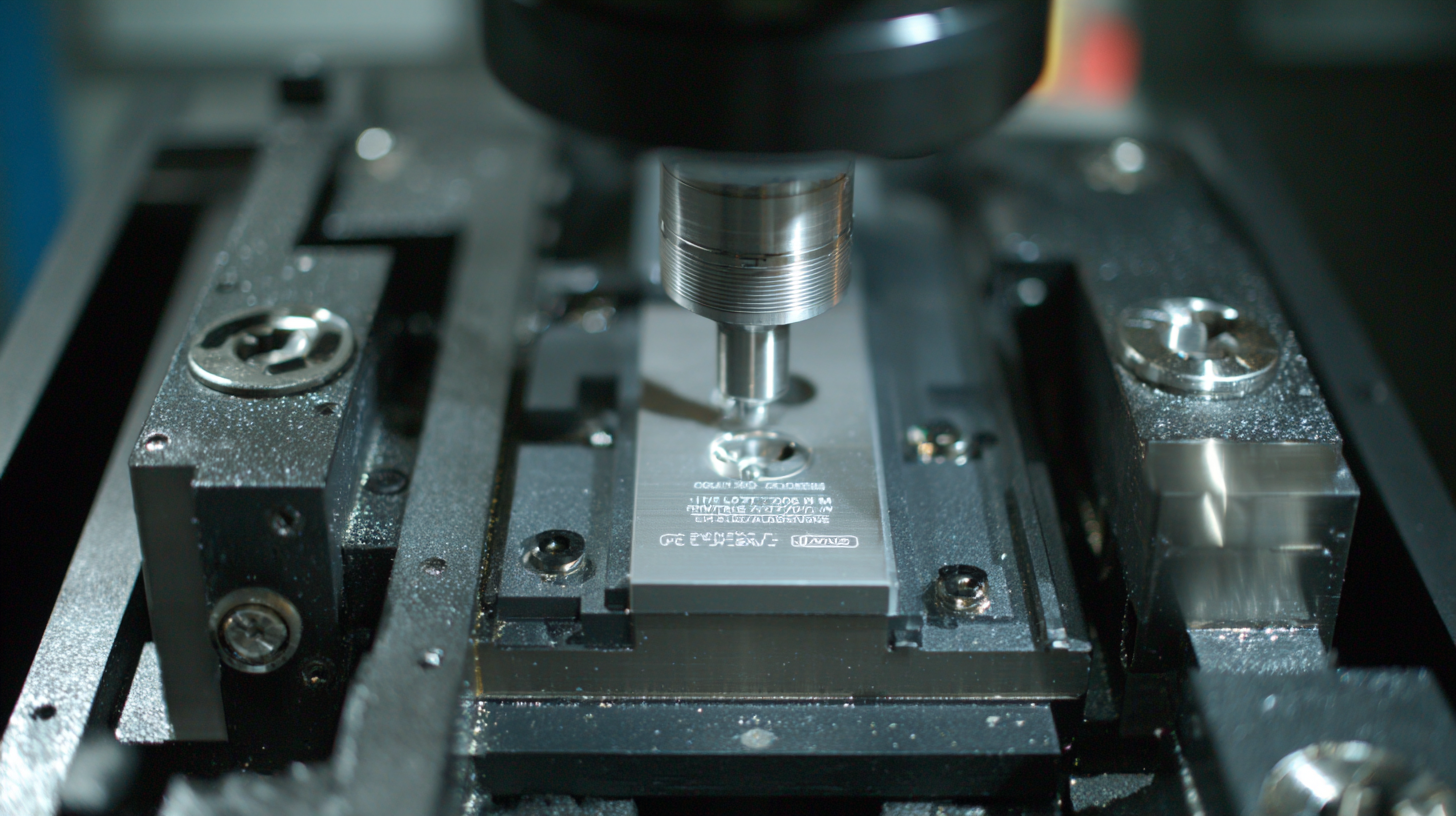

Understanding the fundamentals of CNC milling involves recognizing its key components—such as the CNC machine, tool paths, and programming languages like G-code. A study by Research and Markets noted that the demand for CNC milling services is growing at a CAGR of over 5%, driven by the need for efficient, high-quality production methods. With the capability to produce complex geometries with minimal waste, CNC milling not only enhances precision but also reduces production time, aligning with industry trends towards lean manufacturing practices. Thus, mastering CNC milling is critical for businesses aiming to stay competitive in an ever-evolving market.

In the burgeoning CNC machine market, set to expand from $101.22 billion in 2025 to $195.59 billion by 2032, precision remains a significant focus for manufacturers. Key specifications such as tolerances, surface finish, and material quality play a crucial role in defining the precision in CNC milling. The demand for high-precision components is driving innovation, as companies strive to meet the unique requirements of various industries including aerospace, automotive, and electronics.

One notable trend is the introduction of precision-engineered tools that enhance the efficiency and accuracy of CNC operations. For instance, the development of advanced milling tools, drills, and reamers has revolutionized manufacturing processes. The shift to CNC systems has allowed for more consistent and repeatable production of complex geometries, as seen in the transition experienced by manufacturers adopting new CNC technologies. With high-quality materials and customized specifications now readily available, businesses can achieve a fine surface finish that meets stringent industry standards, ultimately contributing to overall competitiveness in the global market.

When it comes to achieving optimal results in CNC milling, selecting the right materials is paramount. Each material has distinct properties that can significantly influence the effectiveness of the milling process. For example, metals like aluminum and steel are often favored for their durability and machinability, but they require specific tooling and speeds to achieve precision without causing wear. Understanding the characteristics of these materials, such as hardness and thermal conductivity, can help in selecting the appropriate machining parameters, leading to better surface finishes and dimensional accuracy.

Beyond metals, plastics and composites have become increasingly popular in CNC milling due to their versatility and lightweight properties. Materials like acrylic and nylon not only offer ease of machining but also come with distinct challenges like chip formation and melting points that must be managed carefully. Additionally, considering factors like the intended application and final product requirements can guide manufacturers in making informed material choices. By aligning the material selection with the specific goals of the milling project, businesses can unlock the full potential of CNC milling technology and achieve superior outcomes.

In the rapidly evolving landscape of manufacturing, precision and efficiency are paramount, particularly in the realm of CNC milling machines. The CNC machine tools market is projected to reach an impressive US$ 141.61 billion, driven by the surge in manufacturing automation and an intensified demand for precision in production processes. As manufacturers embrace automation, they are experiencing significant enhancements in operational efficiency, thus underscoring the importance of best practices in operating CNC milling machines effectively.

One essential practice for optimizing CNC machine usage involves leveraging advanced CAD/CAM software that streamlines toolpath improvements. These technological innovations help reduce job setup times and enhance the overall speed of production workflows. Additionally, data model-based toolpath generation techniques, which preprocess point cloud data using advanced methods, further boost processing efficiency and yield higher quality outputs. As the integration of digitalization, IoT, and AI reshapes the manufacturing sector, it becomes imperative for operators to stay informed about these advancements to maintain competitive advantage and ensure the sustainable progress of CNC machining practices.

CNC milling has revolutionized machining precision and efficiency, but operators often face issues that can hinder output quality. According to a 2021 report by the Manufacturing Technology Association, downtime due to milling machine failures can reach up to 20% of production time. Common problems, such as tool wear, misalignment, and software glitches, can contribute significantly to this lost productivity. Regular maintenance checks and recalibrating machines can help mitigate these issues, ensuring a smoother operation.

In addressing troubleshooting, it’s essential to leverage data-driven insights. A study published in the Journal of Manufacturing Processes found that implementing a predictive maintenance program can decrease equipment failure by up to 30%. By employing sensors and monitoring software, manufacturers can preemptively identify wear patterns and potential failures, thus improving overall milling output. Moreover, investing in high-quality milling tools tailored to specific materials can further enhance performance, reducing anomalies during production and extending the life of the machinery.

| Specification | Optimal Value | Common Issues | Troubleshooting Tips |

|---|---|---|---|

| Spindle Speed | 5000 - 12000 RPM | Tool Wear | Increase spindle speed and use appropriate feeds. |

| Feed Rate | 100 - 300 mm/min | Poor Surface Finish | Adjust feed rate to match material type. |

| Cutting Depth | 1 - 5 mm | Vibration | Reduce cutting depth to minimize vibrations. |

| Tool Material | High-Speed Steel (HSS), Carbide | Chipping | Select proper tool grade for the material being cut. |

| Coolant Type | Water-Soluble | Overheating | Ensure adequate coolant flow during operation. |