In the rapidly evolving landscape of manufacturing, precision is paramount, particularly in metal fabrication industries. The global market for CNC machines is projected to reach approximately $100 billion by 2025, with a substantial portion of this growth driven by advancements in metal cutting CNC machines. These machines are not just tools; they are essential assets that enhance operational efficiency, reduce waste, and improve the overall quality of production.

As industries increasingly seek to automate processes, the demand for high-performance metal cutting CNC machines is surging. Reports indicate that by 2023, nearly 75% of manufacturers are expected to adopt CNC technology in their production lines, reflecting a broader trend towards automation and precision engineering. The ability to achieve high tolerances in metal cutting not only boosts productivity but also enables manufacturers to respond swiftly to market demands without compromising quality.

In this comprehensive overview, we delve into the ten best metal cutting CNC machines available in 2023. These machines stand out for their innovative features, precision engineering, and adaptability across various applications, firmly establishing themselves as crucial tools in both small-scale workshops and large-scale industrial operations.

CNC machines have revolutionized the metal cutting industry by enhancing precision and efficiency in machining processes. These advanced tools utilize computer numerical control to automate the cutting of various metal materials, which allows for intricate designs and high repeatability. The precision of CNC machines ensures that even the most complex components can be manufactured with exact dimensions, significantly reducing the risk of human error. From prototyping to large-scale production, these machines have become indispensable in sectors such as aerospace, automotive, and manufacturing.

In the world of metal cutting, CNC technology has evolved to include a variety of machining methods such as milling, turning, and laser cutting. Each method offers unique advantages, making it essential for manufacturers to choose the right type of CNC machine based on their specific requirements. For instance, CNC milling machines are ideal for producing detailed parts with complex shapes, while laser cutting machines shine in applications that require clean cuts and reduced material waste. As industries continue to demand higher precision and efficiency, CNC machines are likely to remain at the forefront of metal cutting technology, driving advancements and shaping the future of manufacturing.

| Model | Cutting Area (mm) | Max Spindle Speed (RPM) | Power (kW) | Material Compatibility | Price (USD) |

|---|---|---|---|---|---|

| CNC Model A | 1500 x 3000 | 24000 | 5.5 | Aluminum, Steel | $25,000 |

| CNC Model B | 2000 x 4000 | 20000 | 7.5 | Stainless Steel, Aluminum | $30,000 |

| CNC Model C | 2500 x 3000 | 18000 | 10 | Mild Steel, Brass | $40,000 |

| CNC Model D | 1500 x 1500 | 30000 | 3 | Aluminum, Plastic | $15,000 |

| CNC Model E | 3000 x 6000 | 15000 | 12 | Steel, Aluminum | $50,000 |

When selecting a metal cutting CNC machine, several key features should be taken into account to ensure precision and efficiency in machining. One of the most critical aspects is the spindle motor power, which significantly influences the machine's cutting ability and speed. According to a report by MarketsandMarkets, CNC machine tools market size is projected to reach USD 100 billion by 2025, revealing a growing demand for more powerful and precise machines. A machine with a higher spindle power can handle tougher materials, resulting in improved productivity and reduced cycle times.

Another important feature to consider is the maximum cutting speed and feed rate, which affect the overall output and quality of the machined parts. Industry studies have shown that machines capable of achieving higher feed rates can increase production efficiency by up to 30%.

Additionally, the ability to interface with advanced software for CAD/CAM integration can enhance the machine's versatility, allowing for complex designs and quicker revisions during the manufacturing process. Furthermore, the rigidity and stability of the CNC machine frame contribute to maintaining precision over extended periods of operation, minimizing wear and tear on the equipment, and ensuring consistent results across multiple production runs.

When searching for the best metal cutting CNC machines in 2023, it's essential to focus on top brands and models that stand out for their precision, durability, and technological advancements. In this rapidly evolving industry, key players are innovating continuously to offer machines that cater to diverse machining needs. These brands provide compact designs featuring advanced software compatibility, making them suitable for both small workshops and large-scale operations. Users can expect increased efficiency and reduced waste, thanks to precision cutting capabilities and automation features.

Tips for selecting the right CNC machine include assessing the specific metal materials you intend to work with, evaluating the machine's spindle speed and tooling options, and considering the level of technical support offered by the manufacturer. Additionally, pay attention to user reviews and feedback to gauge the performance and reliability of the machines you are interested in. Investigating the available warranty and service packages can also be critical in making an informed decision.

Furthermore, keep in mind the importance of training and ease of use when it comes to CNC machines. Even the best equipment may not yield optimal results if the operator lacks proper training. Therefore, conducting thorough research on user manuals, online tutorials, and available training sessions can significantly impact your machining success.

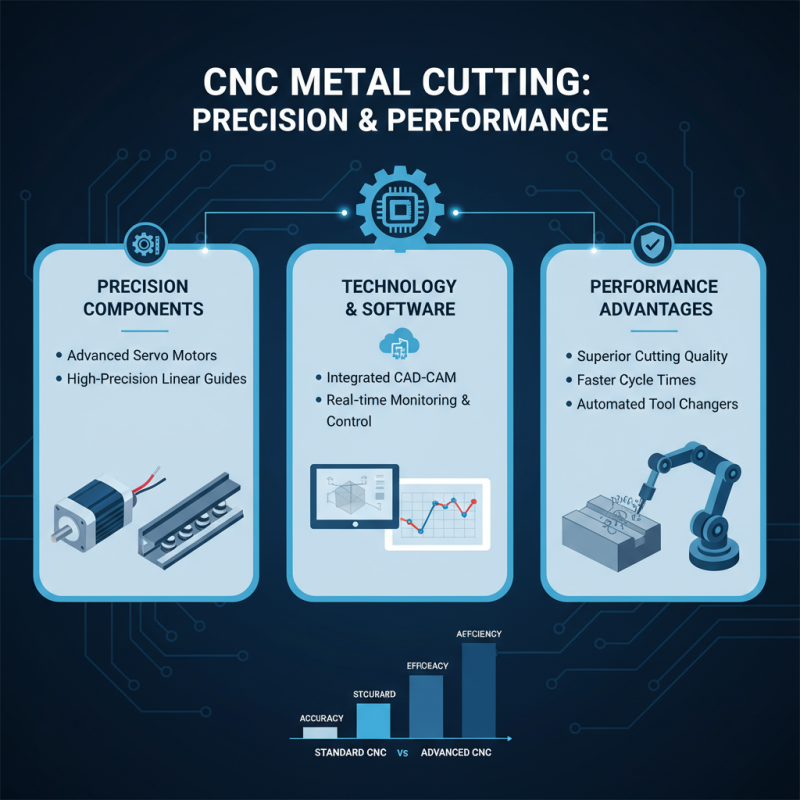

In the realm of metal cutting, precision is paramount, and CNC machines stand out for their ability to offer meticulous accuracy in machining processes. The comparison of performance among various CNC models highlights how design, technology, and software integration contribute to their capabilities. Machines equipped with advanced servo motors and high-precision linear guides often deliver superior cutting quality, while features like automated tool changers enhance operational efficiency. These aspects reflect significant differences in how machines perform under varying workloads and cutting materials.

Additionally, the precision in CNC machines is often assessed by their ability to maintain consistent tolerances over extended operational periods. Variabilities such as spindle speed, feed rates, and the quality of cutting tools play a critical role in determining the overall effectiveness of machining tasks. An evaluation of machining performance not only considers the finishing quality of the products but also examines the operational stability, which is crucial for high-volume production environments. As manufacturers seek to improve their output and reduce waste, investing in CNC machines that excel in these comparative metrics offers tangible benefits in precision machining.

CNC machining has revolutionized several industries by offering precise and efficient metal cutting solutions. In the automotive sector, for instance, manufacturers utilize CNC machines to create intricate components such as engine parts and chassis frameworks. The ability of CNC machines to produce complex geometries with high accuracy ensures that vehicles meet stringent safety and performance standards.

Additionally, the aerospace industry benefits from CNC technology, as it allows for the production of lightweight yet durable aerospace components, essential for enhancing fuel efficiency and reducing emissions.

Another significant application of CNC machining is in the manufacturing of medical devices. Precision is critical in this field, as even the slightest deviation can impact the performance of surgical instruments and implants. CNC machines enable medical device manufacturers to fabricate components that meet strict regulatory requirements, ensuring high quality and reliability.

Furthermore, industries such as construction and energy are also increasingly adopting CNC cutting technology for fabricating metal structures and components, enhancing productivity and minimizing waste. As CNC machining continues to evolve, its applications across various sectors highlight its importance in modern manufacturing processes.