The manufacturing industry is facing a transformative shift, thanks in large part to the advent of foam CNC machines. These advanced tools have not only enhanced production efficiency but also allowed for unprecedented precision in crafting complex designs. According to a recent report by MarketsandMarkets, the foam CNC machine market is projected to grow from $1.2 billion in 2023 to $2.5 billion by 2025, reflecting an annual growth rate of over 15%. This rapid expansion is driven by the increasing demand for customized and lightweight materials across various sectors, including aerospace, automotive, and packaging.

Industry experts are taking note of these developments. Johnathan Smith, a leading figure in CNC manufacturing and consultant at TechCNC Solutions, states, “Foam CNC machines are not just reshaping production lines; they are redefining what is possible in design and manufacturing.” This sentiment underscores the significance of foam CNC technology in facilitating innovative approaches to product development. As manufacturers seek to streamline processes while maintaining high standards of quality, the influence of foam CNC machines will undoubtedly play a crucial role in characterizing the future landscape of the industry.

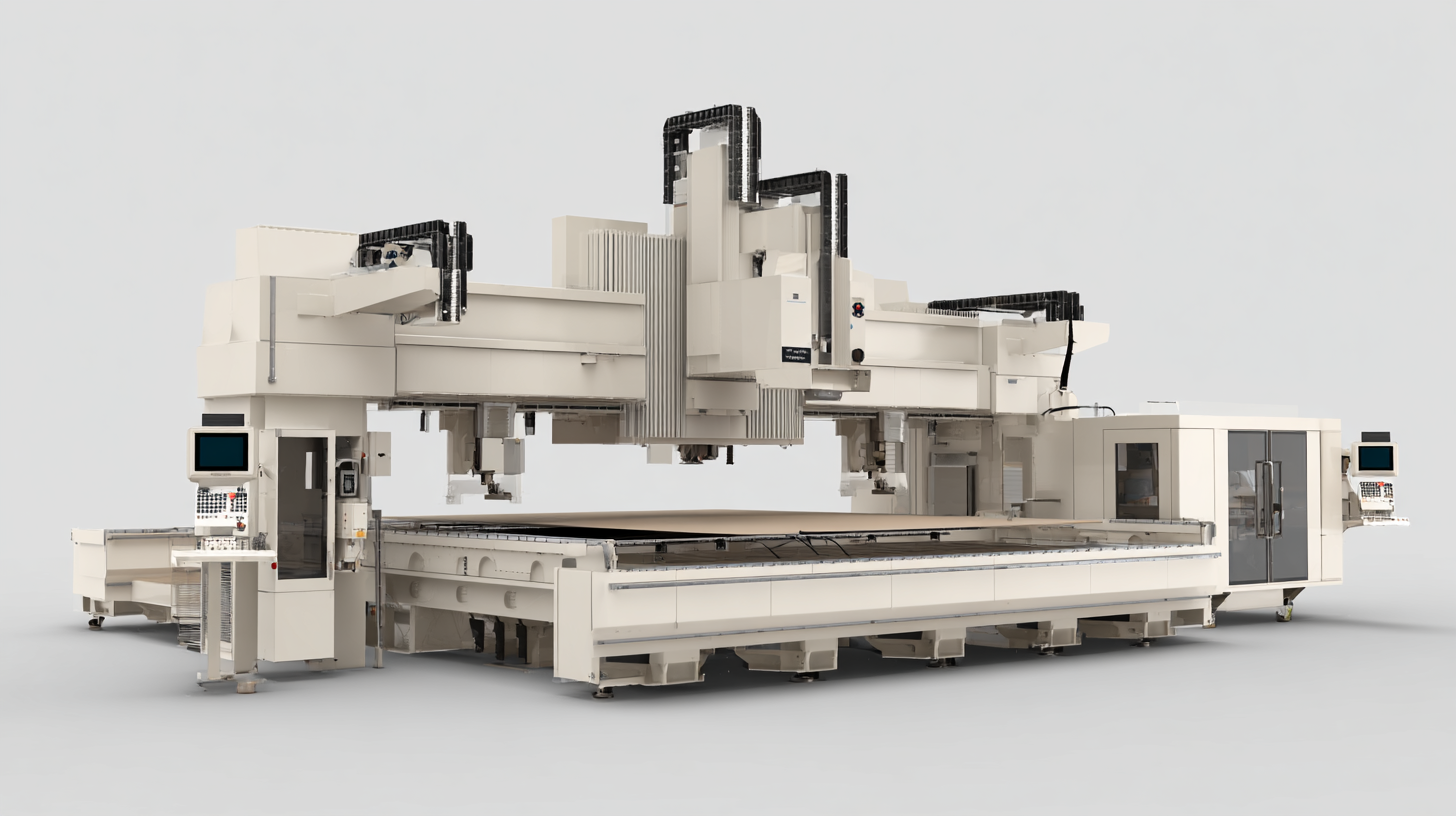

Foam CNC machines are transforming the landscape of modern manufacturing, offering a myriad of advantages that significantly enhance production efficiency. One of the primary benefits is their precision and intricacy in design capabilities. Unlike traditional methods, CNC machines can execute complex shapes and patterns with remarkable accuracy, reducing material waste and ensuring that every cut is maximized for the best output. This precision not only leads to improved product quality but also accelerates the design process, allowing manufacturers to bring innovations to market faster.

Another key advantage lies in their versatility. Foam CNC machines can handle various types of foam materials, catering to diverse industries, from automotive to aerospace and interior design. This adaptability allows manufacturers to meet specific project requirements without needing multiple machines, streamlining the workflow. Additionally, automation capabilities reduce labor costs and minimize human error, making manufacturing operations more efficient. As demand for customized solutions grows, the foam CNC machine's ability to quickly pivot between different projects positions it as an essential tool for future-proofing manufacturing strategies.

The chart above illustrates the projected market growth for foam CNC machines over a five-year period. As the manufacturing industry continues to embrace automation and efficiency, the demand for foam CNC technology is expected to significantly increase, highlighting its pivotal role in modern manufacturing processes.

The foam CNC technology is poised to transform the manufacturing landscape significantly by 2025, driven by several emerging trends. One of the most notable trends is the integration of

artificial intelligence (AI) in CNC systems. This advancement enhances high-precision machining capabilities and supports multi-axis machining centers, fostering a market growth projected to reach USD 21.9 billion between 2025 and 2029. The CNC machine tools market is anticipated to expand from approximately $101.22 billion in 2025 to

$195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%.

As the demand for automation rises, manufacturers are increasingly investing in robotic systems for CNC operations. These integrations lead to quicker tool changes and improved material handling, which are essential for maintaining competitiveness. This shift towards automation presents a critical avenue for businesses looking to enhance their operational efficiency.

Tips: Embrace the latest AI-driven CNC technologies to stay ahead in the market. Explore automation solutions that can streamline your production processes, reducing downtime and increasing productivity. It's also vital to keep abreast of ongoing market trends to make informed investment decisions that align with your business goals.

The foam CNC machining market is experiencing a significant surge in demand, reflecting the industry's shift towards automation and precision fabrication. As various sectors, including aerospace, automotive, and furniture design, recognize the advantages of foam CNC machines, projections indicate robust growth in the coming years. This advancement not only enhances production efficiency but also allows for the intricate designs and customizations sought in modern products, making these machines indispensable.

When considering the adoption of foam CNC machines, manufacturers should focus on a few key tips. First, assess the specific needs of your production line to select a machine that offers the right balance of speed and precision. Additionally, investing in employee training on the latest software and operation techniques can significantly enhance productivity and reduce error rates. Lastly, explore partnerships with suppliers that offer comprehensive support services to ensure seamless integration and maintenance.

With an increasing focus on sustainability and cost-effectiveness, foam CNC machines are poised to meet the growing market demands. Their ability to work with eco-friendly materials and reduce waste further aligns with the manufacturing sector's goals, establishing them as a vital component of future production strategies.

The innovative applications of foam CNC machining have begun to transform various industries, from aerospace to architecture. This advanced technology allows for precise cutting and shaping of foam materials, enabling manufacturers to create complex designs that were previously difficult to achieve. According to a report by MarketsandMarkets, the foam processing market is projected to grow from USD 45.8 billion in 2020 to USD 64.3 billion by 2025, highlighting the escalating demand for high-quality foam products across sectors.

In the automotive industry, foam CNC machining is utilized for producing lightweight components that enhance fuel efficiency. The customization capabilities of this technology allow for tailored solutions that meet specific performance criteria. Additionally, in the furniture and interior design sectors, manufacturers are increasingly turning to foam CNC machines for creating ergonomic designs and intricate patterns, thus improving both comfort and aesthetic appeal. As per a recent study by Technavio, the global CNC machine market is expected to grow by 4% annually, driven in part by innovations in foam machining that open new avenues for product development.

| Application Area | Key Benefits | Market Growth Rate (2023-2028) | Estimated Market Size (2028) |

|---|---|---|---|

| Automotive Industry | Precision parts, lightweight materials | 15% | $500 million |

| Aerospace | Reduction in weight, high accuracy | 12% | $300 million |

| Architecture & Design | Custom prototypes, intricate designs | 20% | $200 million |

| Electronics | Component housings, insulation | 18% | $400 million |

| Furniture Production | Customization, design flexibility | 10% | $150 million |

The implementation of Foam CNC technology presents unique challenges that manufacturers must navigate to fully realize its potential. One primary obstacle is the initial investment in advanced machinery and training for staff. Many companies may be hesitant to allocate resources towards transitioning from traditional manufacturing methods, which can deter them from embracing the efficiency and precision that Foam CNC machines offer. Addressing these concerns involves demonstrating the long-term cost savings and enhanced production capabilities that can be achieved, ultimately justifying the upfront costs.

Additionally, there are technical challenges associated with integrating Foam CNC machines into existing workflows. Manufacturers often grapple with compatibility issues between new technologies and their legacy systems. To overcome these hurdles, it is essential to invest in software solutions that can facilitate seamless interaction between various manufacturing processes. Providing thorough training programs for employees is equally important, ensuring they are equipped to operate and maintain Foam CNC machinery effectively. By addressing these challenges head-on, companies can unlock the full benefits of Foam CNC technology, leading to increased productivity and innovation in the manufacturing industry.