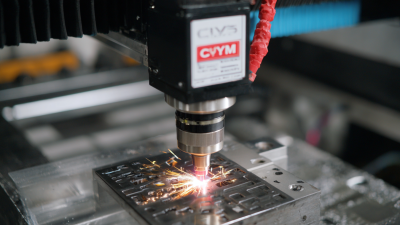

The rapid advancement of technology has positioned CNC machine laser cutting machines at the forefront of manufacturing innovation. According to a report by MarketsandMarkets, the global CNC laser cutting machine market was valued at $3.55 billion in 2020 and is projected to reach $5.84 billion by 2025, with a CAGR of 10.5%. This growth is driven by the increasing demand for precision and efficiency across various industries, from automotive to aerospace. Businesses are recognizing the need for sophisticated cutting solutions that not only enhance manufacturing speed but also reduce material waste. As we venture into the future, understanding the evolving capabilities and potential applications of CNC machine laser cutting technology is crucial.

This blog aims to provide a comprehensive checklist of the key trends, innovations, and considerations shaping the revolution in CNC machining, ensuring that industry players are well-equipped to harness these advancements effectively.

As CNC laser cutting technology continues to evolve, emerging technologies are significantly enhancing precision in various industrial applications. Innovations in software algorithms and artificial intelligence are allowing for precise control over cutting parameters, which has been shown to improve accuracy by up to 30%. According to a report by MarketsandMarkets, the CNC laser cutting market is projected to reach $7.5 billion by 2026, driven by the demand for high-quality cutting solutions across numerous sectors including automotive, aerospace, and electronics.

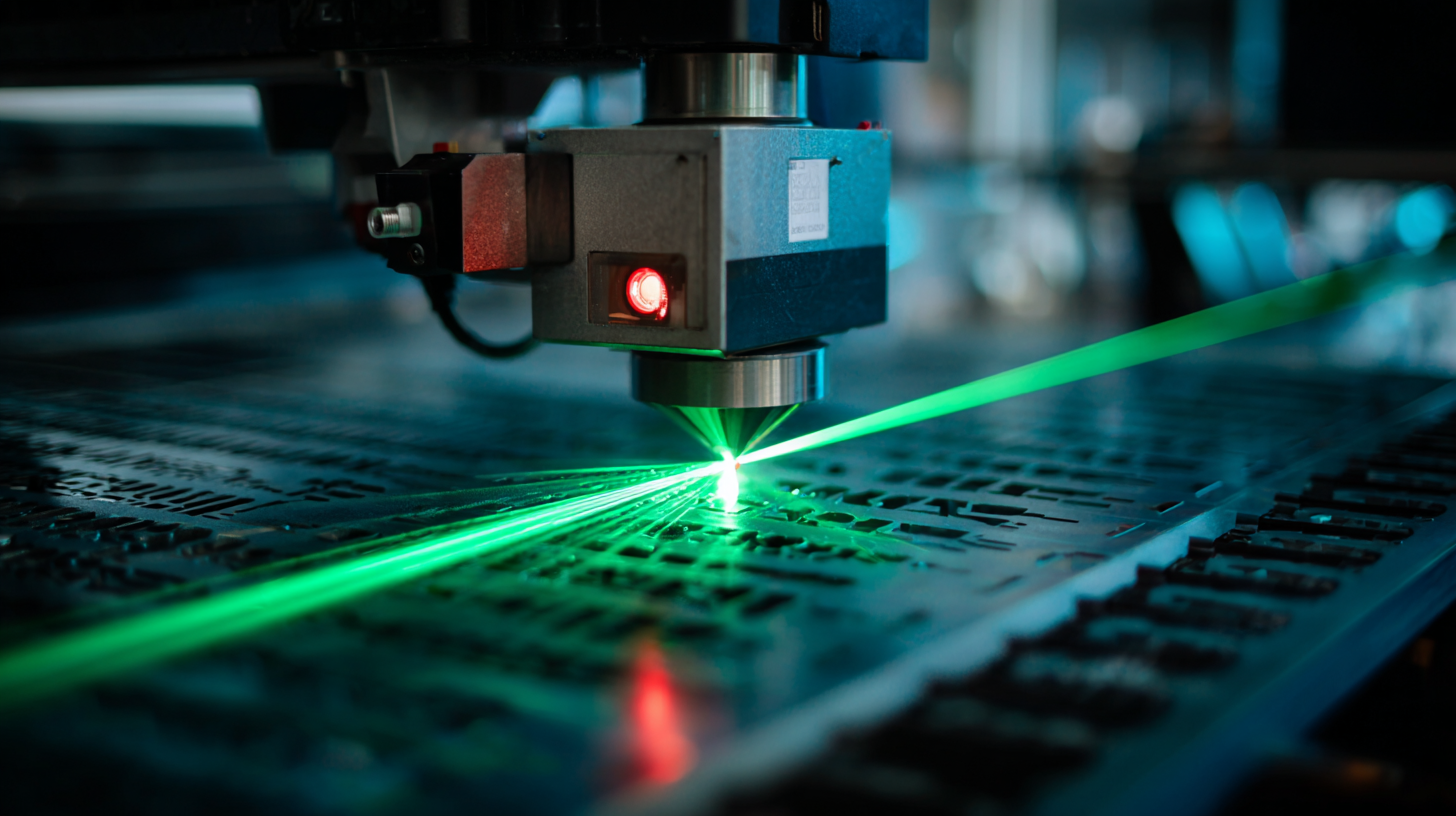

Moreover, advancements in laser sources, such as fiber lasers and ultrafast lasers, are making the cutting process more efficient and precise. Fiber lasers, for instance, have a smaller beam diameter and can focus light into a tighter spot, which increases the cutting speed and quality significantly. A study published in the Journal of Manufacturing Processes indicates that the introduction of these technologies can reduce material waste by as much as 20%, providing both an economic and environmental advantage.

Tip: Regular maintenance of CNC laser cutting machines is crucial for sustaining precision. Ensure that lenses and mirrors are kept clean and properly aligned to prevent degradation in cutting quality. Additionally, investing in training for operators on the latest software will maximize the potential of these emerging technologies.

| Technology | Description | Impact on Precision | Potential Applications |

|---|---|---|---|

| Fiber Laser Technology | Uses a solid-state laser to produce a focused beam for cutting | Increases cutting speed and reduces heat-affected zones | Metal fabrication, automotive parts, and aerospace components |

| CO2 Laser Systems | Utilizes CO2 gas to generate a high-intensity laser beam | Highly effective for cutting thicker materials | Woodworking, textile industry, and acrylic cutting |

| Laser Beam Profiling | Analyzes the beam quality to optimize the cutting process | Enhances kerf width consistency and edge quality | Precision engineering, micro-machining, and medical devices |

| Adaptive Cutting Technology | Automatically adjusts parameters based on real-time feedback | Improves accuracy and reduces material waste | Aerospace manufacturing, custom metalworking, and prototyping |

| Integrated CAD/CAM Systems | Combines design and manufacturing processes into one software | Enhances design accuracy and cutting efficiency | Product design, architectural modeling, and signage production |

The applications of CNC laser cutting technology span across various industries, demonstrating its versatility and impact on modern manufacturing processes. According to a recent market report, the global CNC laser cutting machine market is anticipated to grow significantly, with projections indicating a CAGR of over 7% through 2033. This growth can be attributed to the increasing demand for precision in manufacturing, especially in sectors like automotive, aerospace, and electronics, where intricate designs are paramount.

One of the driving forces behind this technological advancement is the shift towards sustainable manufacturing practices. Laser cutting technology not only enhances efficiency but also minimizes material waste, aligning with the industry's move towards eco-friendly solutions. For instance, laser-based technologies have been highlighted as a critical innovation in promoting sustainable manufacturing, enabling manufacturers to adopt cleaner and more efficient processes. The integration of advanced laser technologies, such as fiber and CO2 laser cutting, has revolutionized the way industries approach fabrication, allowing for faster production times and higher-quality outputs. As the demand for both productivity and sustainability grows, CNC laser cutting technology is set to play a pivotal role in shaping the future of manufacturing.

CNC laser cutting technology has seen significant advancements, leading to successful implementations across various industries. A case study involving the automotive sector highlighted how a leading manufacturer reduced production time by 30% by integrating CNC laser cutting machines into their workflow. According to a report by MarketsandMarkets, the global CNC laser cutting market is projected to reach $5.8 billion by 2026, emphasizing the growing reliance on this technology for efficiency and precision.

Another striking example can be found in the aerospace industry, where a prominent company utilized CNC laser cutting to streamline component production. This implementation not only enhanced the accuracy of intricate designs but also decreased material waste by approximately 15%. The International Society of Automation reported that 70% of manufacturers who adopted laser cutting technologies experienced improved productivity, underscoring the transformative impact of CNC laser cutting on modern manufacturing processes. These case studies illustrate that embracing this technology is crucial for companies seeking to maintain a competitive edge in an increasingly automated landscape.

As we look ahead, the trends in CNC laser cutting technology are poised to revolutionize manufacturing processes across various industries. One of the most significant advancements is the integration of artificial intelligence and machine learning into CNC systems. These technologies enable machines to optimize cutting paths and adjust parameters in real-time based on material properties, ensuring precision and reducing waste. This not only enhances efficiency but also expands the capabilities of laser cutting, allowing for more intricate designs and superior finishing.

Another key trend is the development of more versatile and powerful laser sources. Innovations such as fiber lasers and ultra-fast laser systems are pushing the boundaries of what CNC laser cutting can achieve. These technologies offer higher cutting speeds and greater material compatibility, enabling operators to work with a wider range of substances, from metals to plastics. Furthermore, with the increase in automation and smart manufacturing, CNC laser cutting machines are becoming integral components of industry 4.0, facilitating seamless integration into automated workflows and data management systems. This evolution marks an exciting new chapter for CNC laser cutting, promising enhanced productivity and limitless possibilities for creativity in design.

As industries increasingly prioritize sustainability, CNC laser cutting technology is evolving to meet these demands. According to a report by Grand View Research, the global laser cutting market is expected to reach $6.83 billion by 2027, driven not only by efficiency but also by a shift towards eco-friendly manufacturing practices. CNC laser cutting machines are known for their precision and reduced waste, making them a cornerstone in sustainable production lines. By utilizing advanced software and real-time monitoring, these systems minimize material usage while maximizing operational efficiency.

Moreover, energy efficiency in laser cutting systems has significantly improved over the past few years, with many new models consuming up to 30% less energy compared to their predecessors. According to a publication by the International Energy Agency, optimizing energy consumption in industrial processes is crucial; it's estimated that energy efficiency improvements could reduce global energy demand by 12% by 2040. This trend reflects a growing commitment to both enhanced productivity and responsible manufacturing. As companies embrace these innovations, CNC laser cutting not only facilitates superior quality and speed but also advances a green agenda that resonates with today's market values.