As industries continue to evolve, the significance of advanced manufacturing technologies, such as plastic cutting CNC machines, has become increasingly evident. The global market for CNC machines is projected to reach **$100 billion by 2025**, with the rising demand for precision and efficiency driving growth. According to a recent report by ResearchAndMarkets, the plastic CNC machining segment is expected to witness a **compound annual growth rate (CAGR) of 6.5%**, reflecting the surge in applications across automotive, aerospace, and consumer goods sectors. The upcoming **138th China Import and Export Fair** in 2025 serves as an ideal platform to explore the future trends of plastic cutting CNC machines, showcasing innovations that enhance productivity, reduce waste, and cater to the growing need for customized solutions. This event will not only highlight technological advancements but also facilitate discussions on sustainability and resource efficiency in the manufacturing landscape.

At the 138th China Import and Export Fair in 2025, the spotlight will undoubtedly shine on emerging technologies in plastic cutting CNC machines. With advancements in automation and artificial intelligence, these machines are expected to achieve unparalleled precision and efficiency. The integration of AI-driven algorithms will enable them to adapt to varying material properties and cutting requirements in real-time, thereby reducing waste and enhancing production rates. Moreover, predictive maintenance technologies will play a crucial role in minimizing downtime, ensuring that manufacturers can maximize their output.

Additionally, the incorporation of smart sensors will revolutionize the operational capability of plastic cutting CNC machines. These sensors will monitor parameters such as temperature, vibration, and cutting force, allowing operators to make informed decisions swiftly. This level of interconnectivity will also support Industry 4.0 initiatives, paving the way for fully automated production lines. As the demand for customized plastic products continues to rise, the evolution of these machines will not only boost productivity but also foster innovation in design and manufacturing processes, positioning China as a leader in the global machinery market.

The global market for CNC (Computer Numerical Control) machines is poised for significant growth, driven by the increasing demand for precision manufacturing across various industries. The CNC machines market size is expected to reach $575.4 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.6% from its valuation of $250.1 billion in 2018. This growth reflects a broader trend in manufacturing, where businesses are increasingly adopting advanced automation and digital technologies to enhance production efficiency and reduce operational costs.

At the 138th China Import and Export Fair in 2025, the spotlight will likely be on the latest innovations in CNC machinery. As manufacturers seek to meet the rising demand for environmentally friendly and efficient cutting solutions, suppliers are expected to transition from conventional methods to more automated systems. With the global machine tool market projected to grow from $1326.3 billion in 2025 to $2294.6 billion by 2032, at a CAGR of 8.1%, the fair will present a prime opportunity for industry players to showcase cutting-edge technologies that cater to evolving market needs.

As the 138th China Import and Export Fair 2025 approaches, the spotlight on sustainability in manufacturing processes, particularly in plastic cutting, has never been brighter. According to a recent report by MarketsandMarkets, the global market for eco-friendly cutting technology is projected to grow at a CAGR of 8.5% from 2023 to 2028. This growth is largely driven by the increasing demand for sustainable materials and processes, prompting companies to innovate in ways that reduce waste and energy consumption.

As the 138th China Import and Export Fair 2025 approaches, the spotlight on sustainability in manufacturing processes, particularly in plastic cutting, has never been brighter. According to a recent report by MarketsandMarkets, the global market for eco-friendly cutting technology is projected to grow at a CAGR of 8.5% from 2023 to 2028. This growth is largely driven by the increasing demand for sustainable materials and processes, prompting companies to innovate in ways that reduce waste and energy consumption.

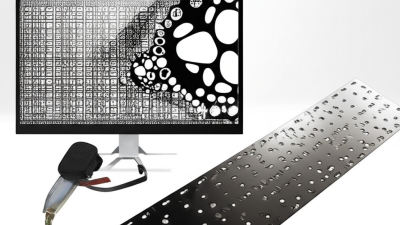

Recent advancements in CNC machines are redefining the plastic cutting industry with a focus on sustainable practices. Innovations such as water jet technology and advanced laser cutting methods minimize scrap material while maximizing precision. A study by Grand View Research highlights that the adoption of energy-efficient CNC machines can reduce operational costs by up to 30%, showcasing the economic benefits alongside the environmental impacts.

Tips: To stay ahead in the industry, businesses should invest in training programs that emphasize eco-friendly practices for CNC operators. Additionally, regularly upgrading machinery to the latest models can greatly enhance sustainability efforts. Consider partnering with suppliers who prioritize sustainable materials, further integrating green practices into your production line.

The integration of AI and automation in CNC machine operations is set to revolutionize the plastic cutting industry, especially as seen at the 138th China Import and Export Fair in 2025. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.8 billion by 2025, with automation technologies playing a critical role in this growth. Advanced AI algorithms are now enabling CNC machines to optimize cutting paths, enhancing precision and reducing waste, which is vital in plastic fabrication where material efficiency significantly impacts production costs.

Furthermore, the advent of smart CNC systems equipped with IoT connectivity allows for real-time monitoring and predictive maintenance, minimizing downtime and increasing operational efficiency. A survey conducted by Deloitte indicates that 78% of manufacturers believe that AI-driven automation will lead to enhanced productivity. At the upcoming fair, innovative exhibitors are expected to showcase how these technologies facilitate adaptive production processes capable of responding to market demand fluctuations swiftly. This trend not only promises to elevate productivity levels but also encourages sustainable practices by maximizing resource utilization in the plastics sector.

| Feature | Current Status (2023) | Predicted Advancement (2025) | Potential Impact |

|---|---|---|---|

| AI Integration | Moderate usage in operations | Full integration for real-time adjustments | Increased efficiency and precision |

| Automation Level | Semi-automatic processes | Fully automated workflows | Reduced labor costs and errors |

| Material Compatibility | Limited to specific plastics | Broader range of materials including composites | Expanded market applications |

| User Interface | Basic interface design | Intuitive, AI-assisted interfaces | Enhanced user experience and accessibility |

| Energy Efficiency | Moderate energy consumption | Smart energy management systems | Lower operational costs and environmental impact |

The 138th China Import and Export Fair in 2025 is set to showcase significant advancements in plastic cutting CNC machines, reflecting the industry's rapid evolution. Key players in the market, such as HAAS Automation and DMG Mori, are anticipated to unveil innovative technologies that enhance precision and efficiency in plastic cutting processes. A recent industry report by Market Research Future projects that the global CNC machine market is expected to reach $106 billion by 2025, with a substantial portion driven by advancements in plastic processing capabilities.

Innovations at the fair will likely include smart CNC machines integrated with IoT technologies, enabling real-time monitoring and data analytics for improved production outcomes. According to a report by ResearchAndMarkets, the adoption of smart manufacturing technologies is expected to increase the productivity of CNC operations by 30% in the coming years. Additionally, eco-friendly materials and sustainable manufacturing practices are gaining traction, with companies investing in greener alternatives that align with global sustainability goals. This emphasis on innovation and sustainability will shape the competitive landscape, driving players to differentiate themselves through state-of-the-art technology and environmental stewardship.