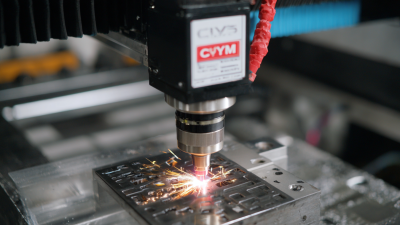

In the ever-evolving landscape of manufacturing, laser cutting stands out as a groundbreaking technology that is transforming production processes across various industries. This advanced method harnesses the precision and efficiency of lasers to create intricate designs and shapes with remarkable accuracy, setting a new standard in the realm of fabrication. As businesses strive to remain competitive, the adoption of laser cutting not only enhances productivity but also minimizes waste and reduces operational costs. From automotive to aerospace, the applications of laser cutting are vast, making it an essential tool for manufacturers seeking to innovate and elevate their offerings. In this ultimate guide, we will delve into seven compelling reasons why laser cutting is revolutionizing the manufacturing sector today, highlighting its benefits, versatility, and the future it promises for industries worldwide.

Laser cutting is transforming the landscape of manufacturing by significantly enhancing accuracy and precision. By utilizing a high-powered laser beam, this method enables intricate designs in materials such as metal, plastic, and wood. Reports indicate that the adoption of laser cutting technology can improve operational efficiency by up to 30% in various sectors. For instance, the integration of a galvanometer-based scan system in battery manufacturing showcases how laser cutting optimizes both speed and precision, crucial in today's fast-paced production environments.

Tips for achieving optimal results with laser cutting include regularly calibrating your equipment to maintain precision and investing in high-quality lenses to ensure a clean cut. Ensuring proper material selection is also essential; materials like stainless steel and acrylic yield superior results when laser cut, leading to minimized waste and enhanced quality.

Additionally, as demand for smaller and more complex components grows, laser technology proves to be pivotal in sectors like semiconductor manufacturing. With photonics technology driving innovations, manufacturers can leverage laser cutting to meet increasingly stringent specifications while reducing production times. Incorporating laser technology not only boosts accuracy but also contributes to a more sustainable manufacturing process by minimizing waste.

Laser cutting technology is proving to be a game changer in the manufacturing landscape, particularly in terms of cost-efficiency. A report by MarketsandMarkets estimates that the global laser cutting machine market will reach USD 4.86 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth is largely driven by the technology's ability to minimize waste and reduce production time, directly impacting overhead costs. Traditional cutting methods often result in significant material loss, whereas laser cutting can achieve precision cuts with minimal waste, enhancing overall productivity.

Moreover, the operational savings associated with laser cutting extend beyond material efficiency. According to a report from Grand View Research, the increased automation of manufacturing processes through laser technology can lead to a reduction in labor costs by up to 30%. Automation not only streamlines processes but also reduces the likelihood of human error, further enhancing the efficiency of production lines. As industries continue to seek ways to optimize expenditure, the adoption of laser cutting technologies offers an attractive solution to reduce overheads while increasing manufacturing capabilities.

Laser cutting technology has emerged as a pivotal force in the manufacturing sector, driven significantly by its material versatility. Unlike traditional cutting methods, laser cutting can process a diverse array of materials, including metals, plastics, wood, glass, and even textiles.

According to a market analysis by Research and Markets, the global laser cutting market is projected to grow from $4.1 billion in 2021 to $8.5 billion by 2026, highlighting the increasing adoption of this technology across various industries.

One of the key advantages of laser cutting lies in its precision and efficiency, enabling manufacturers to create intricate designs that other cutting methods cannot achieve. A study by MarketsandMarkets reveals that laser cutting not only reduces waste but also enhances productivity by up to 30% when compared to conventional cutting techniques. This capability to handle multiple materials with high accuracy allows manufacturers to expand their product lines and enter new markets, ultimately pushing the boundaries of what is possible in manufacturing today. As industries continue to embrace innovation, laser cutting stands out as a crucial enabler of complex and rapid manufacturing solutions.

Laser cutting technology is making significant waves in the manufacturing sector, particularly for its sustainability benefits. By utilizing focused laser beams, manufacturers can achieve precision cuts with minimal waste, effectively reducing the amount of leftover material. Traditional cutting methods often generate significant scrap, whereas laser cutting targets only the necessary material, promoting efficient resource use.

Eco-friendly solutions are further enhanced through the innovative use of materials. Many manufacturers are now adopting recyclable and biodegradable materials that can be seamlessly integrated with laser cutting processes. This not only supports the circular economy but also minimizes the carbon footprint associated with production.

**Tips for Sustainable Laser Cutting**

1. **Choose Eco-Conscious Materials:** Opt for materials that are either recyclable or sourced sustainably to enhance the eco-friendliness of your final product.

2. **Regular Maintenance:** Keep your laser cutting equipment in top shape to ensure it operates efficiently, minimizing energy consumption and reducing operational waste.

3. **Optimize Designs for Material Use:** Streamline designs to use less material and allow for more intricate cuts that can lead to a significant reduction in wasted resources.

Laser cutting technology is transforming the manufacturing landscape by significantly enhancing production workflows and speed. One of the most compelling advantages of laser cutting is its precision. Unlike traditional cutting methods, lasers deliver unparalleled accuracy, enabling manufacturers to produce intricate designs with minimal material waste. This precision reduces the need for rework, thereby accelerating the overall production process. Furthermore, the ability to automate laser cutting operations allows factories to achieve higher levels of efficiency, as machines can operate continuously without the need for prolonged human intervention.

In addition to precision, laser cutting offers exceptional versatility across various materials, including metals, plastics, and wood. This adaptability means that manufacturers can quickly pivot to meet changing market demands without investing in extensive equipment changes. The speed of laser cutting also plays a crucial role; processes that once took hours can now be completed in a fraction of the time. As a result, companies can fulfill orders faster and respond promptly to customer needs, ultimately enhancing customer satisfaction and boosting competitive advantage in a rapidly evolving market.