In the ever-evolving landscape of manufacturing, the foam die cutting machine has emerged as a pivotal tool for enhancing production efficiency across various industries. According to a recent market report by Grand View Research, the global die-cutting machine market is projected to reach approximately $7 billion by 2025, underscoring the growing demand for precision and speed in manufacturing processes. By leveraging advancements in technology, firms can significantly optimize their workflows, reduce waste, and improve product consistency.

This blog aims to explore innovative strategies and practical tips for maximizing the efficiency of foam die cutting machines, ensuring that businesses not only meet their operational goals but also stay competitive in a rapidly changing market.

Foam die cutting machines are essential tools for various industries, including packaging, automotive, and aerospace, where precision and efficiency are paramount. Understanding the basics of these machines reveals their capabilities to streamline processes significantly. According to a report by MarketsandMarkets, the global die cutting machine market is expected to reach $5.5 billion by 2026, driven by the increasing demand for automation and precision in manufacturing. These machines can handle various foam types, enabling manufacturers to produce intricate shapes and designs while reducing waste material.

Foam die cutting machines are essential tools for various industries, including packaging, automotive, and aerospace, where precision and efficiency are paramount. Understanding the basics of these machines reveals their capabilities to streamline processes significantly. According to a report by MarketsandMarkets, the global die cutting machine market is expected to reach $5.5 billion by 2026, driven by the increasing demand for automation and precision in manufacturing. These machines can handle various foam types, enabling manufacturers to produce intricate shapes and designs while reducing waste material.

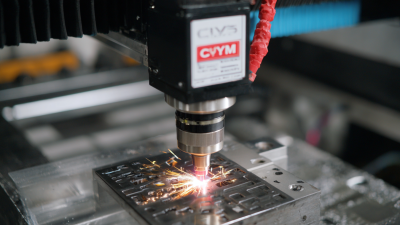

The fundamental operation of foam die cutting involves using a sharp die to cut through the material with extreme accuracy. A study from the International Journal of Industrial Technology highlights that the efficiency of foam die cutting can enhance production speed by up to 30% compared to traditional cutting methods. This efficiency is attributed to the machines' ability to execute multiple cuts simultaneously and their compatibility with automated feeding systems. As industries continue to adopt advanced technologies, understanding the basics of foam die cutting machines will help manufacturers stay competitive and optimize their production lines.

When selecting a high-efficiency foam die cutting machine, there are several key features that can significantly enhance performance and productivity. First and foremost, precision cutting is crucial; look for machines with advanced blade technology and adjustable settings that allow for intricate designs without compromising the quality of the cut. A machine’s ability to accurately handle various foam densities and thicknesses can also save time and reduce waste during production.

Another important feature to consider is automation. Models equipped with automatic feed systems can increase workflow efficiency, minimizing downtime between cuts and allowing for higher throughput. Additionally, user-friendly interfaces and programmable settings can simplify operation, enabling operators to make quick adjustments and execute multiple patterns without extensive training. When these features are combined, they not only streamline the cutting process but also contribute to a more consistent and reliable output, ultimately maximizing overall efficiency in foam cutting tasks.

This chart illustrates key efficiency metrics for foam die cutting machines, highlighting areas such as cutting speed, blade durability, setup time, material waste, and energy consumption. Optimal performance in these metrics is essential for maximizing the efficiency of production processes.

Maintaining foam die cutting equipment is crucial for maximizing efficiency and prolonging the lifespan of machinery. According to a report by the Association for Manufacturing Technology (AMT), proper maintenance can improve machine efficiency by up to 20%. Regularly scheduled maintenance not only ensures the machine operates at optimal levels but also reduces the risk of unexpected breakdowns. Implementing a routine that includes checking blades for sharpness and wear, lubricating moving parts, and ensuring accurate calibration can markedly enhance performance.

Maintaining foam die cutting equipment is crucial for maximizing efficiency and prolonging the lifespan of machinery. According to a report by the Association for Manufacturing Technology (AMT), proper maintenance can improve machine efficiency by up to 20%. Regularly scheduled maintenance not only ensures the machine operates at optimal levels but also reduces the risk of unexpected breakdowns. Implementing a routine that includes checking blades for sharpness and wear, lubricating moving parts, and ensuring accurate calibration can markedly enhance performance.

Moreover, utilizing high-quality materials is essential for effective die cutting. Research from the Flexible Packaging Association indicates that using superior foam quality can lead to a decrease in material wastage by approximately 15%. This reduction not only increases efficiency during production but also contributes to cost savings. Operators should be educated on the importance of selecting the right foam thickness and density that align with the capabilities of their die-cutting machine, thus facilitating smoother operations and better end-products. Regular training sessions can further equip staff with the necessary skills to identify maintenance needs proactively, ensuring optimal performance at all times.

When it comes to foam die cutting, optimizing your workflow is essential for enhancing efficiency and productivity. The layout of your workspace plays a crucial role in this process. Start by arranging your foam die cutting machines in a way that minimizes unnecessary movement. Place the cutting area in close proximity to the receiving and packing stations, so that finished products can be quickly processed and shipped. This strategic layout not only speeds up the production cycle but also reduces the risk of damages during handling.

In addition to layout, refining your cutting process is vital. Implementing standard operating procedures (SOPs) ensures that every team member is on the same page, reducing confusion and errors. Train staff on best practices, such as the proper setup of dies, material alignment, and maintenance routines. Utilizing cutting-edge software to monitor production metrics can further streamline your operations. By analyzing data on cycle times and material usage, you can identify bottlenecks and make data-driven adjustments to enhance overall efficiency, ensuring your foam die cutting operation runs as smoothly as possible.

When using foam die cutting machines, there are several common mistakes that operators should avoid to maximize efficiency and achieve the best results. One prevalent issue is not correctly aligning the foam material with the cutting die. Misalignment can lead to uneven cuts, wasted material, and longer production times. Always take the time to ensure accurate positioning before starting the cutting process.

Another mistake is underestimating the importance of blade maintenance. Dull blades can cause fraying, inconsistent cuts, and increased wear on the machine. Regularly inspect and sharpen blades, or replace them when necessary to maintain optimal performance. Additionally, be sure to clean the die cutting machine regularly to prevent buildup that can compromise efficiency.

Lastly, many operators overlook the significance of selecting the right foam type for the project. Different foams have varying densities and properties, which can impact cutting performance and the end product's quality. Always evaluate the specifications of the foam to ensure it meets the requirements of your project. By being mindful of these common pitfalls, you can enhance the overall effectiveness of your foam die cutting operations.