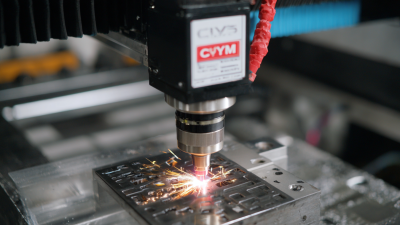

In the rapidly evolving landscape of modern manufacturing, the quest for efficiency and precision remains paramount. Industrial CNC milling machines stand at the forefront of this revolution, enabling manufacturers to achieve superior performance levels and streamline production processes. As industries increasingly embrace automation and advanced machining capabilities, understanding how to maximize the potential of these powerful machines becomes essential.

This ultimate guide will delve into the intricacies of industrial CNC milling machines, exploring strategies and best practices that can significantly enhance operational efficiency. From optimizing tool paths to selecting the right materials, we will equip you with the insights needed to elevate your manufacturing processes and stay competitive in today's fast-paced market. Join us as we navigate the complexities of CNC milling and unlock the true potential of your industrial capabilities.

When selecting the right CNC milling machine for your production needs, it’s essential to consider both the technological advancements in the field and your specific production requirements. Recent developments in digital twin technology have revolutionized CNC machine design and operation, contributing to more precise and efficient manufacturing processes. According to industry reports, the global CNC milling machine market is poised to grow substantially, driven by the demand for automation and precision in manufacturing. By incorporating AI and advanced analytics, manufacturers can optimize their operational workflows and reduce downtime significantly.

The key to maximizing efficiency lies in understanding the specific features your production demands. For instance, machines offering high-speed spindle options can enhance productivity, while systems with advanced integrated software can facilitate smoother programming and operation. Reports indicate that companies employing advanced CNC solutions experience up to a 30% increase in production efficiency. Additionally, evaluating the machine's scalability is critical as companies look to invest in technologies that not only meet current requirements but can also adapt to future advancements in manufacturing. By carefully considering these factors, manufacturers can select CNC milling machines that not only align with their production goals but also contribute to sustainable growth.

When it comes to optimizing CNC milling operations in modern manufacturing, having the right software and tools is crucial for maximizing efficiency. Advanced CNC programming software allows operators to create intricate designs and simulations, reducing the likelihood of errors before machine execution. Tools like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) integrate seamlessly, enabling users to transform conceptual designs into precise operational plans. This integration not only streamlines the workflow but also enhances communication between design and production teams.

In addition to software, leveraging specialized tools can significantly impact milling efficiency. Toolpath optimization techniques can minimize machining time and material waste. Utilizing real-time monitoring tools allows operators to track machine performance and make adjustments on the fly, ensuring minimal downtime. Furthermore, selecting the right cutting tools tailored to specific materials and applications plays a vital role in achieving superior quality and efficiency. By combining these essential software and tools, manufacturers can create a highly efficient CNC milling environment, driving productivity and competitiveness in the market.

In the fast-evolving landscape of modern manufacturing, the efficiency of CNC milling processes is pivotal to achieving competitive advantage. Key metrics for measuring this efficiency include cycle time, tool usage, and material waste. According to a report by the National Institute of Standards and Technology, optimizing cycle time can lead to a reduction of production costs by up to 25%, showcasing the critical role of speed in milling operations.

In the fast-evolving landscape of modern manufacturing, the efficiency of CNC milling processes is pivotal to achieving competitive advantage. Key metrics for measuring this efficiency include cycle time, tool usage, and material waste. According to a report by the National Institute of Standards and Technology, optimizing cycle time can lead to a reduction of production costs by up to 25%, showcasing the critical role of speed in milling operations.

Another vital metric is tool utilization, which measures the percentage of time tools are actively engaged in the milling process. Industry studies suggest that maximizing tool usage can enhance productivity by as much as 30%. Furthermore, minimizing material waste not only improves cost-effectiveness but also bolsters environmental sustainability. A recent survey highlighted that manufacturers implementing efficient milling processes could reduce scrap rates by over 20%, significantly impacting their bottom line and ecological footprint.

Emphasizing these metrics allows manufacturers to focus on continuous improvement. Real-time data monitoring enables quick adjustments, leading to an average increase in overall equipment effectiveness (OEE) by 15%. With precision engineering becoming increasingly important, leveraging these key efficiency metrics is essential for manufacturers looking to thrive in a competitive market.

In modern manufacturing, maximizing efficiency in CNC milling is crucial, not only for reducing costs but also for enhancing overall productivity. A recent report from the American Society of Mechanical Engineers (ASME) indicates that manufacturing companies can achieve up to a 30% reduction in waste by implementing strategic milling techniques. One highly effective technique is the optimization of tool paths, which reduces the time equipment is idle and minimizes the material left over after machining. Studies show that advanced tool-path algorithms can lead to a significant decrease in cycle times, translating into increased throughput.

Another approach involves utilizing predictive maintenance practices. Research from the National Institute of Standards and Technology (NIST) suggests that predictive maintenance can enhance machine uptime by 20-25%. By proactively addressing equipment issues before they lead to significant downtime, manufacturers can ensure continuous operation and reduce unnecessary waste. Furthermore, integrating automation in CNC milling processes allows for precise control over cutting parameters, leading to optimal material usage and reduced scrap rates. By focusing on these innovative techniques, modern manufacturers can not only enhance productivity but also create a more sustainable manufacturing environment.

The integration of automation and artificial intelligence (AI) into CNC milling processes is revolutionizing modern manufacturing, significantly enhancing performance and productivity. According to a recent report by McKinsey, companies using AI and automation can expect a productivity increase of up to 50% in their operations. This leap is particularly evident in CNC milling environments where automated systems can optimize machining parameters in real-time, reducing cycle times and minimizing material waste.

Moreover, the implementation of AI-driven predictive maintenance in CNC machines can reduce downtime by as much as 30%, as highlighted in a study by Gartner. By continuously monitoring machine performance and predicting failures before they occur, manufacturers can maintain operational efficiency and avoid costly interruptions. Additionally, AI algorithms can analyze vast amounts of data from machine operations to recommend adjustments, ensuring that mills run at peak efficiency throughout their lifecycle.

As manufacturers increasingly incorporate these advanced technologies, the potential to scale production while maintaining precision also expands. The combination of CNC milling with automation and AI not only enhances speed and efficiency but also facilitates greater flexibility in manufacturing processes, allowing for more complex and customized production runs. Statistics from the International Federation of Robotics indicate that the use of industrial robots in CNC milling applications is expected to grow by 25% annually, reflecting an industry-wide shift towards more integrated and intelligent manufacturing systems.

This chart illustrates the average production efficiency of CNC milling machines integrated with automation and AI technologies compared to traditional setups over a six-month period.