In recent years, plastic laser cutting has emerged as a game-changing technology in the manufacturing landscape, significantly enhancing precision and efficiency in various industries. According to a report by MarketsandMarkets, the global laser cutting machine market is expected to reach $5.8 billion by 2026, with plastic laser cutting being a key driver of this growth due to its ability to produce intricate designs with minimal waste. This method leverages high-powered lasers to cut through a range of plastic materials, offering advantages such as reduced production time and superior edge quality compared to traditional cutting techniques. As manufacturers strive for greater efficiency and sustainability, plastic laser cutting not only meets these demands but also opens up new possibilities for innovation in product design and customization. This blog will explore the fundamentals of plastic laser cutting and its transformative impact on manufacturing processes.

Plastic laser cutting is a transformative process that utilizes focused laser beams to cut through various plastic materials with precision and efficiency. This technology operates on the principle of vaporizing the plastic at the point of contact with the laser, resulting in clean and accurate cuts. Unlike traditional cutting methods, laser cutting minimizes material waste, an important factor given that the global plastic waste is projected to reach 1.3 billion metric tons by 2030, according to the World Economic Forum.

One of the significant advantages of plastic laser cutting lies in its ability to deliver intricate designs without compromising the integrity of the material. Reports from the Market Research Future indicate that the laser cutting machine market is expected to grow at a rate of 6.5% annually, highlighting the increasing adoption of this technology in manufacturing sectors. This trend is particularly relevant as industries aim to optimize their processes and reduce environmental impact.

**Tips**: When considering plastic laser cutting for your projects, ensure to choose the right type of plastic that is suitable for laser processing. Additionally, always consult with a professional laser cutting service to determine the optimal settings and avoid any risks of material deformation.

Laser cutting has become a game-changer in the manufacturing sector, particularly for plastic materials. Compared to traditional cutting methods, which often involve mechanical blades and significant manual labor, laser cutting offers unparalleled precision and efficiency. The ability of lasers to create intricate designs with tight tolerances minimizes waste and reduces the need for extensive post-processing. This level of accuracy not only enhances the overall quality of the products but also streamlines the manufacturing workflow, significantly reducing lead times.

Another notable advantage of laser cutting is its versatility. It can effortlessly handle various types of plastics, whether they are rigid sheets or flexible films. Unlike traditional methods, which may require different tools for different materials, laser cutters can adapt to cut through various thicknesses and compositions seamlessly. This flexibility allows manufacturers to innovate and experiment with new designs and applications, fostering a creative environment where possibilities are endless. Additionally, the energy efficiency of laser technology contributes to lower operational costs, making it an economically viable solution in an increasingly competitive market.

Plastic laser cutting has transformed manufacturing processes across various industries, enabling precise cuts and intricate designs that traditional methods often struggle to achieve. The technology utilizes high-powered lasers to cut through plastic materials with remarkable accuracy, resulting in clean edges and minimized waste. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach $5.69 billion by 2025, highlighting the growing reliance on this technology in sectors like automotive, aerospace, and consumer goods.

In the automotive industry, for instance, plastic laser cutting is employed to create components such as dashboards and interior panels. This method not only enhances production speed but also accommodates lightweight designs, which contribute to improved fuel efficiency. Additionally, the medical sector utilizes laser cutting for producing intricate parts in devices and packaging, ensuring high standards of hygiene and precision. A study from Research and Markets indicates that the healthcare segment alone is expected to grow by 7.5% annually, further driving innovations in laser technology for customized solutions that meet specific regulatory requirements. Overall, the application of plastic laser cutting is rapidly evolving, specifically aligning with the needs of modern manufacturing.

| Industry | Application | Materials Used | Advantages |

|---|---|---|---|

| Automotive | Custom parts manufacturing | ABS, Polycarbonate | Precision, reduced waste |

| Aerospace | Component fabrication | PTFE, Acetal | Weight reduction, high accuracy |

| Electronics | Enclosures and panels | Polypropylene, PVC | Smooth edges, quick prototyping |

| Medical | Surgical instruments | Polyethylene, Nylon | Sterility, precision cutting |

| Packaging | Custom shapes and labels | PET, HDPE | Versatile designs, minimal waste |

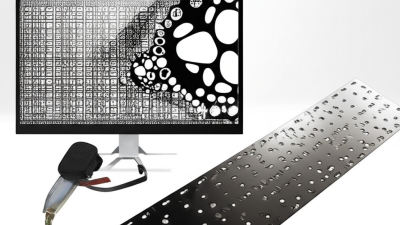

Plastic laser cutting is transforming manufacturing processes by offering remarkable cost efficiency and enhanced production speed. Unlike traditional cutting methods, which may require extensive tooling and setup time, laser cutting utilizes a high-powered laser to achieve precise cuts in various plastic materials. This means manufacturers can minimize waste and reduce the time spent on preparation, leading to significant savings in production costs. The precision of laser cutting also allows for intricate designs that may be impossible to achieve through other methods, further broadening the application possibilities for businesses.

Moreover, when we compare production speed, laser cutting stands out as a superior option. The technology enables continuous and automated cutting, which accelerates the overall production cycle. This rapid processing capability allows manufacturers to meet increasing market demands without sacrificing quality. By integrating laser cutting into their processes, companies can enhance their operational efficiency and responsiveness, ultimately leading to improved competitiveness in the ever-evolving landscape of manufacturing. With these advantages, it’s clear that plastic laser cutting is not just a trend but a revolutionizing force in the industry.

This chart compares the average production speed and cost efficiency of plastic laser cutting against traditional manufacturing methods across various industries. The data highlights the advantages of adopting laser cutting technology in modern manufacturing processes.

The advancement of plastic laser cutting technology is poised to reshape manufacturing processes significantly. As industries evolve, the demand for precision and efficiency in production has intensified, making laser cutting an invaluable tool. This technology facilitates intricate designs and cleaner cuts, which not only enhances product quality but also optimizes material usage. The ability to cut a variety of plastics with high accuracy opens a realm of possibilities for sectors ranging from automotive to textiles, ensuring manufacturers can respond quickly to market needs.

Looking ahead, several trends indicate where plastic laser cutting technology is heading. First, the integration of artificial intelligence and machine learning is expected to improve cutting processes by enabling smarter decision-making and automated adjustments. Moreover, advancements in laser sources, such as fiber lasers, will likely promote higher speed and energy efficiency in plastic processing. Sustainability remains a crucial focus, and innovations are anticipated in materials and processes that minimize waste and energy consumption. As the plastic laser cutting landscape continues to evolve, these trends will not only help manufacturers gain a competitive edge but also contribute to more environmentally friendly practices in the industry.