In the ever-evolving landscape of manufacturing, the advent of plastic laser cutting technology stands out as a transformative force, significantly enhancing efficiency and precision. This innovative approach allows manufacturers to achieve intricate designs and clean cuts with minimal material waste, offering a more sustainable alternative to traditional cutting methods. As industries across the globe increasingly recognize the benefits of precision and speed, understanding the mechanics of plastic laser cutting becomes essential. This article delves into the cutting-edge innovations that underpin this technology, exploring how it optimizes production processes and meets the growing demand for high-quality components. Readers will gain insights into the advantages of adopting plastic laser cutting technology, along with tips on implementing this advanced method to elevate their manufacturing capabilities.

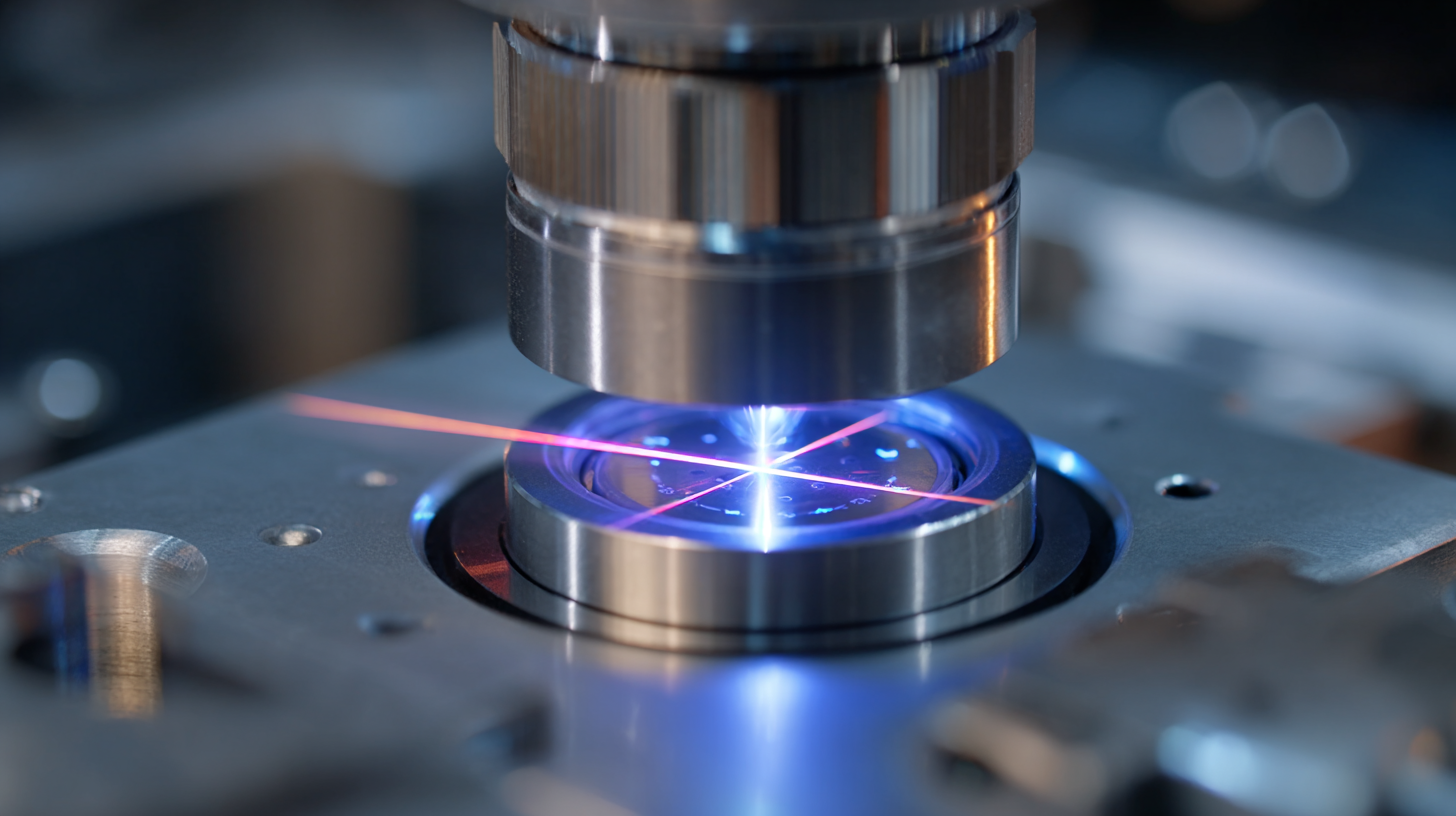

Plastic laser cutting technology has emerged as a transformative force in the manufacturing sector, offering unprecedented precision and efficiency in processing plastic materials. Unlike traditional cutting methods, laser cutting utilizes high-powered light beams to vaporize materials, resulting in clean and intricate cuts with minimal waste. This precision enables manufacturers to create complex designs that were previously difficult to achieve, enhancing the overall quality of the final products.

In addition to precision, the speed of plastic laser cutting is a significant advantage for manufacturers. This technology allows for quicker turnaround times, leading to increased productivity and reduced operational costs. Furthermore, the ability to easily adjust laser settings means that manufacturers can switch between different types of plastics and thicknesses without the need for extensive retooling. As a result, industries ranging from automotive to electronics are increasingly adopting plastic laser cutting technology to optimize their production lines and meet evolving consumer demands. This revolutionary approach not only streamlines manufacturing processes but also sets the stage for sustainable practices by minimizing material wastage.

| Feature | Description | Benefits | Application Areas |

|---|---|---|---|

| Precision Cutting | Utilizes focused laser beams for accurate and intricate cuts. | Improves product quality and reduces material waste. | Automotive, Electronics, Medical Devices |

| Speed | Faster cutting speeds compared to traditional methods. | Enhances manufacturing productivity. | Packaging, Signage, Prototype Manufacturing |

| Flexibility | Easily adapts to various material types and thicknesses. | Supports diverse product designs and customizations. | Consumer Goods, Aerospace, Textile Industry |

| Automation | Integration with automated systems for streamlined operations. | Reduces labor costs and enhances efficiency. | Manufacturing Plants, Assembly Lines |

| Low Heat Impact | Minimizes thermal distortion of materials due to low heat input. | Preserves material integrity and prevents deformation. | Medical Components, Optical Devices |

Recent advancements in plastic laser cutting technology have introduced a new era of efficiency in manufacturing processes. One of the key innovations is the development of high-power fiber lasers, which significantly enhance cutting speed and precision. These lasers offer a higher energy density compared to traditional CO2 lasers, allowing for cleaner cuts with minimal kerf width. This not only improves the quality of the finished product but also reduces material waste, contributing to a more sustainable manufacturing process.

Recent advancements in plastic laser cutting technology have introduced a new era of efficiency in manufacturing processes. One of the key innovations is the development of high-power fiber lasers, which significantly enhance cutting speed and precision. These lasers offer a higher energy density compared to traditional CO2 lasers, allowing for cleaner cuts with minimal kerf width. This not only improves the quality of the finished product but also reduces material waste, contributing to a more sustainable manufacturing process.

Another critical innovation lies in the implementation of advanced automation systems. By integrating laser cutting machines with computer numerical control (CNC) and real-time monitoring systems, manufacturers can optimize their workflows and reduce downtime. These systems enable predictive maintenance, ensuring that potential issues are identified before they disrupt production. Furthermore, automation enhances repeatability and consistency across production batches, leading to decreased variability and improved overall product quality.

Traditional cutting methods, such as saws, routers, and shears, have long been the backbone of manufacturing processes. These methods typically involve physical contact between the tool and the material, which can lead to issues like tool wear, inconsistent cut quality, and substantial material waste. Operators often face challenges managing intricate designs, as traditional methods may struggle with precision in tight tolerances. Additionally, the operational costs are elevated due to slower cutting speeds and the necessity for extensive post-processing procedures to achieve the desired finish.

In contrast, plastic laser cutting technology offers a revolutionary approach to manufacturing, emphasizing efficiency and precision. Laser cut technology utilizes focused light beams to slice through materials without direct contact, greatly reducing wear on tools and allowing for more complex shapes to be cut with unparalleled accuracy. This method not only minimizes material waste but also accelerates production times, enabling manufacturers to respond quickly to market demands. The capability to produce fine details and automate the process significantly enhances overall productivity, positioning laser cutting as a superior alternative to conventional techniques in modern manufacturing environments.

The emergence of plastic laser cutting technology has significantly impacted industry standards and production speed across various sectors. According to a report by MarketsandMarkets, the laser cutting market is projected to grow from $2.1 billion in 2020 to $3.5 billion by 2025, demonstrating a compound annual growth rate (CAGR) of 10.5%. This surge is largely attributed to the technology's ability to cut complex shapes rapidly and with high precision, reducing the need for secondary machining processes that can slow down production.

Moreover, the introduction of plastic laser cutting systems allows manufacturers to achieve production speeds that are up to 20% faster than traditional cutting methods. A study from the International Journal of Advanced Manufacturing Technology reveals that laser cutting can eliminate costly materials waste by up to 30%, further enhancing overall efficiency. As a result, companies can not only meet but exceed industry standards regarding output quality and operational agility, positioning themselves favorably in a competitive landscape where speed and precision are paramount.

This chart illustrates the increased production speed and efficiency resulting from the adoption of plastic laser cutting technology in the manufacturing industry over a five-year period.

The advancements in laser cutting technology are poised to revolutionize the manufacturing sector, enhancing efficiency and precision. As per market predictions, the laser cutting equipment market is expected to reach a substantial size of 368.5 billion yuan by 2024, illustrating a rapid growth trajectory since 2019. This surge reflects the increasing demand for more sophisticated manufacturing processes that laser cutting provides, enabling businesses to achieve higher production rates and lower operational costs.

Furthermore, the CNC laser processing system market is projected to see a compound annual growth rate (CAGR) of 10.25%, with an estimated value of 5.45 billion dollars in 2022, potentially reaching 8.56 billion dollars by 2030. Such figures indicate a significant shift towards automated and precise manufacturing solutions, which are critical for industries that rely heavily on cutting-edge technology.

Additionally, the global CO2 cutting machine market is also anticipated to expand, expecting to reach approximately 2.748 billion dollars by 2033, representing a CAGR of 4.9%. This trend underscores the importance of continuous innovations in laser technology that drive efficiency and reliability in manufacturing processes.