The global manufacturing landscape is undergoing a remarkable transformation, with China's role as a powerhouse at the forefront. According to a report by the China National Automotive Industry Corporation, China's plastic manufacturing market is projected to reach approximately $138 billion by 2025, emphasizing the growing demand for precision tools in the sector. Among these tools, the plastic cutting CNC machine stands out as a critical asset in enhancing manufacturing efficiency and product quality. This machine not only streamlines the cutting process but also offers unparalleled accuracy and repeatability, which are essential for meeting the diverse needs of modern manufacturing. As industries increasingly focus on automation and innovation, understanding how to leverage the capabilities of the best plastic cutting CNC machines will be pivotal for manufacturers aiming to stay competitive in an ever-evolving market.

The global manufacturing landscape is undergoing a remarkable transformation, with China's role as a powerhouse at the forefront. According to a report by the China National Automotive Industry Corporation, China's plastic manufacturing market is projected to reach approximately $138 billion by 2025, emphasizing the growing demand for precision tools in the sector. Among these tools, the plastic cutting CNC machine stands out as a critical asset in enhancing manufacturing efficiency and product quality. This machine not only streamlines the cutting process but also offers unparalleled accuracy and repeatability, which are essential for meeting the diverse needs of modern manufacturing. As industries increasingly focus on automation and innovation, understanding how to leverage the capabilities of the best plastic cutting CNC machines will be pivotal for manufacturers aiming to stay competitive in an ever-evolving market.

The evolution of CNC technology has profoundly transformed China's manufacturing landscape, elevating it to new levels of efficiency and precision. In recent years, there has been a notable shift towards advanced CNC machinery, particularly in industries requiring intricate processing like plastic cutting. This advancement is not merely a trend; it reflects the growing demand for high-quality products amid fierce global competition. The integration of sophisticated CNC cutting machines has enabled manufacturers to streamline operations, reduce waste, and enhance product consistency.

Looking forward, the market dynamics continue to evolve, with forecasts indicating significant growth in CNC machine sectors. For instance, the desktop CNC machine market is projected to surge from approximately $399.9 billion in 2024 to $369.56 billion by 2032, emphasizing the increasing reliance on automation in production processes. This rapid development in CNC technology not only reinforces China's position as a manufacturing powerhouse but also promises to enable companies to meet the ever-changing demands of a global marketplace. As manufacturers harness the capabilities of cutting-edge CNC machines, they are well-equipped to unleash the full potential of China's manufacturing sector.

| CNC Machine Model | Cutting Speed (mm/min) | Max Thickness (mm) | Power Consumption (kW) | Weight (kg) |

|---|---|---|---|---|

| Model A | 3000 | 20 | 5 | 800 |

| Model B | 2500 | 25 | 4.5 | 750 |

| Model C | 3500 | 15 | 6 | 900 |

| Model D | 4000 | 22 | 5.5 | 850 |

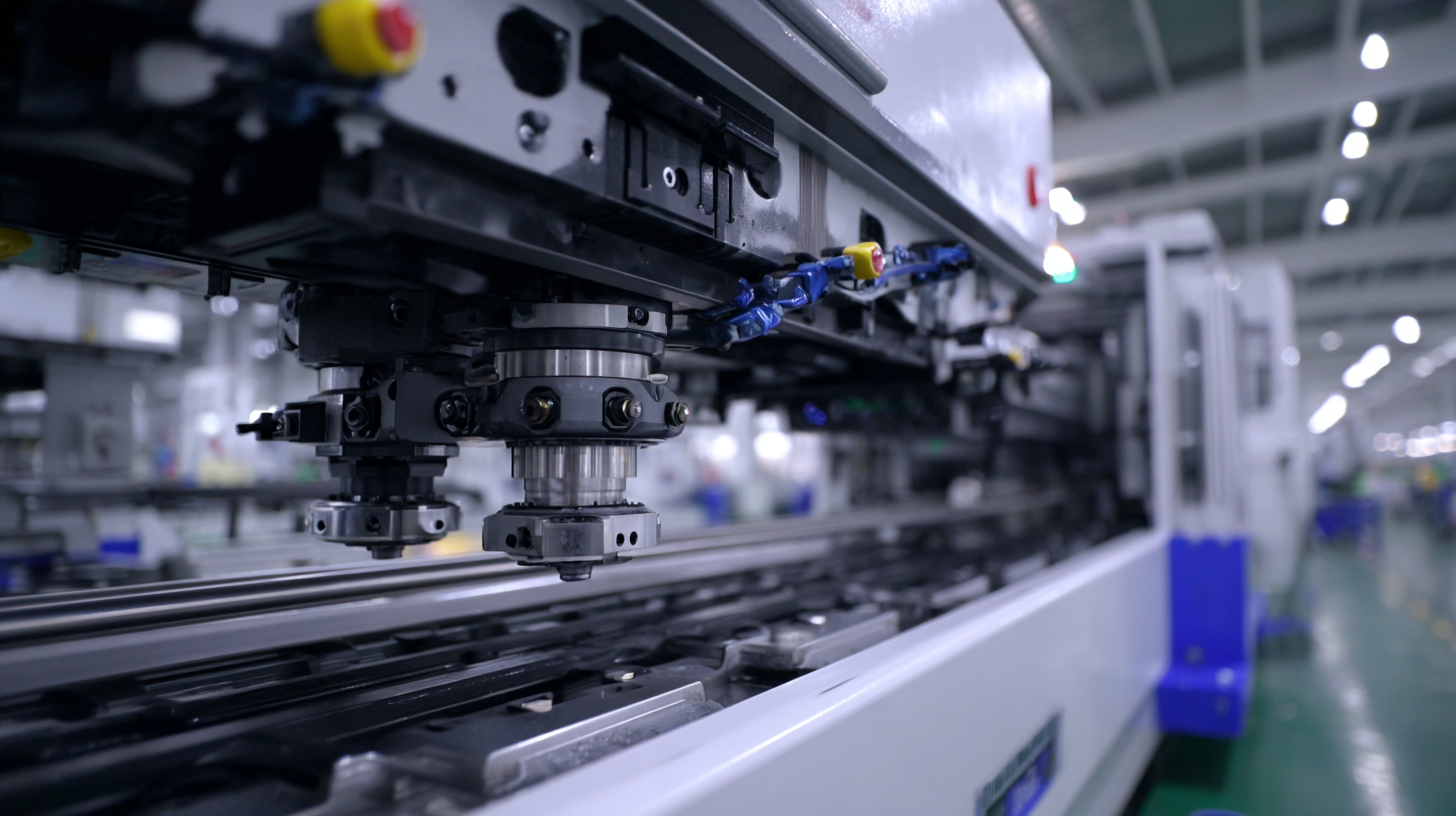

The evolution of plastic cutting CNC machines has significantly transformed the manufacturing landscape in China, enhancing efficiency and productivity in various industries. One of the key features that set top-tier machines apart is their advanced control systems. These systems not only allow for precise cutting operations but also enable users to program complex designs with ease. As a result, manufacturers can achieve tighter tolerances and reduce material wastage, leading to both cost savings and improved product quality.

Another essential characteristic is the versatility of tooling options available with modern CNC machines. High-quality machines offer interchangeable cutting tools that can handle a range of plastic materials, from soft polymers to more rigid composites. This flexibility enables manufacturers to adapt quickly to changing market demands, producing customized solutions without extensive downtime or additional investments. Additionally, features like automated loading and unloading systems streamline operations further, allowing for higher throughput and faster turnaround times while minimizing manual labor. As China continues to advance its manufacturing capabilities, investing in these sophisticated plastic cutting CNC machines is crucial for staying competitive in the global market.

In the evolving landscape of manufacturing, the debate between traditional and CNC plastic cutting methods highlights a significant transformation in how products are made. Traditional plastic cutting techniques often involve manual processes that can be time-consuming and inconsistent in quality. In contrast, CNC (Computer Numerical Control) plastic cutting machines offer enhanced precision and efficiency, with the ability to execute complex designs and patterns that would be incredibly difficult to achieve manually. Reports suggest that CNC machining can reduce production time by up to 75% while minimizing waste, which is crucial in a resource-sensitive environment.

The impact of these advanced manufacturing methods can be observed in various sectors, including electronics, where high-demand products require rapid production cycles without compromising quality. For instance, predictions indicate that new flagship devices will see significant innovation in their design and materials, aided by CNC technologies that allow for intricate internal structures and lightweight components. A recent market analysis highlighted that CNC cutting machines can increase the production speed by 30-50%, allowing companies to respond swiftly to market demands. As industries continue to embrace these advanced techniques, the gap between traditional and modern manufacturing will likely widen, paving the way for further innovations in product development.

CNC machines have emerged as crucial tools in modern manufacturing, especially within China's ever-evolving industrial landscape. By integrating advanced technology, these machines enable precision cutting and shaping of various materials, including plastics, which are fundamental to numerous industries. The role of CNC machines extends beyond mere efficiency; they significantly contribute to sustainable manufacturing practices by minimizing waste and optimizing resource utilization. With their ability to execute complex designs with high accuracy, CNC machines reduce the amount of raw material wasted during the production process, thereby lowering the environmental impact.

Moreover, the automation offered by CNC technology enhances operational consistency and quality, reducing the likelihood of human error. This reliability not only leads to cost savings but also allows manufacturers to adhere to stricter environmental regulations. By implementing CNC machines in their production lines, companies can ensure a streamlined process that aligns with sustainability goals. In a market increasingly focused on eco-friendly practices, leveraging such technology positions manufacturers as leaders in responsible production, enabling them to meet consumer demands for sustainable goods while maintaining profitability.

The future of China's manufacturing sector is poised for significant transformation with advancements in CNC technology. As the global CNC machine market is projected to grow from $101.2 billion in 2025 to $195.59 billion by 2032, representing a compound annual growth rate (CAGR) of 9.9%, China is strategically positioned to harness these developments. The country's manufacturing value added reached an impressive 33 trillion yuan in 2023, leading the world by share and showcasing its pivotal role in the global supply chain.

However, trends such as the decline in electric vehicle investments are influencing overall order volumes, particularly affecting key sectors like automotive and electronics. Reports indicate the CNC controller market is expected to increase from $33.66 million in 2025 to $228.7 million by 2033, highlighting the importance of innovation in precision manufacturing. With robust policy support and a clear roadmap under initiatives like the "14th Five-Year Plan," China's manufacturing industry is on track to accelerate its transformation into a smart manufacturing powerhouse, ultimately redefining the landscape of global production.