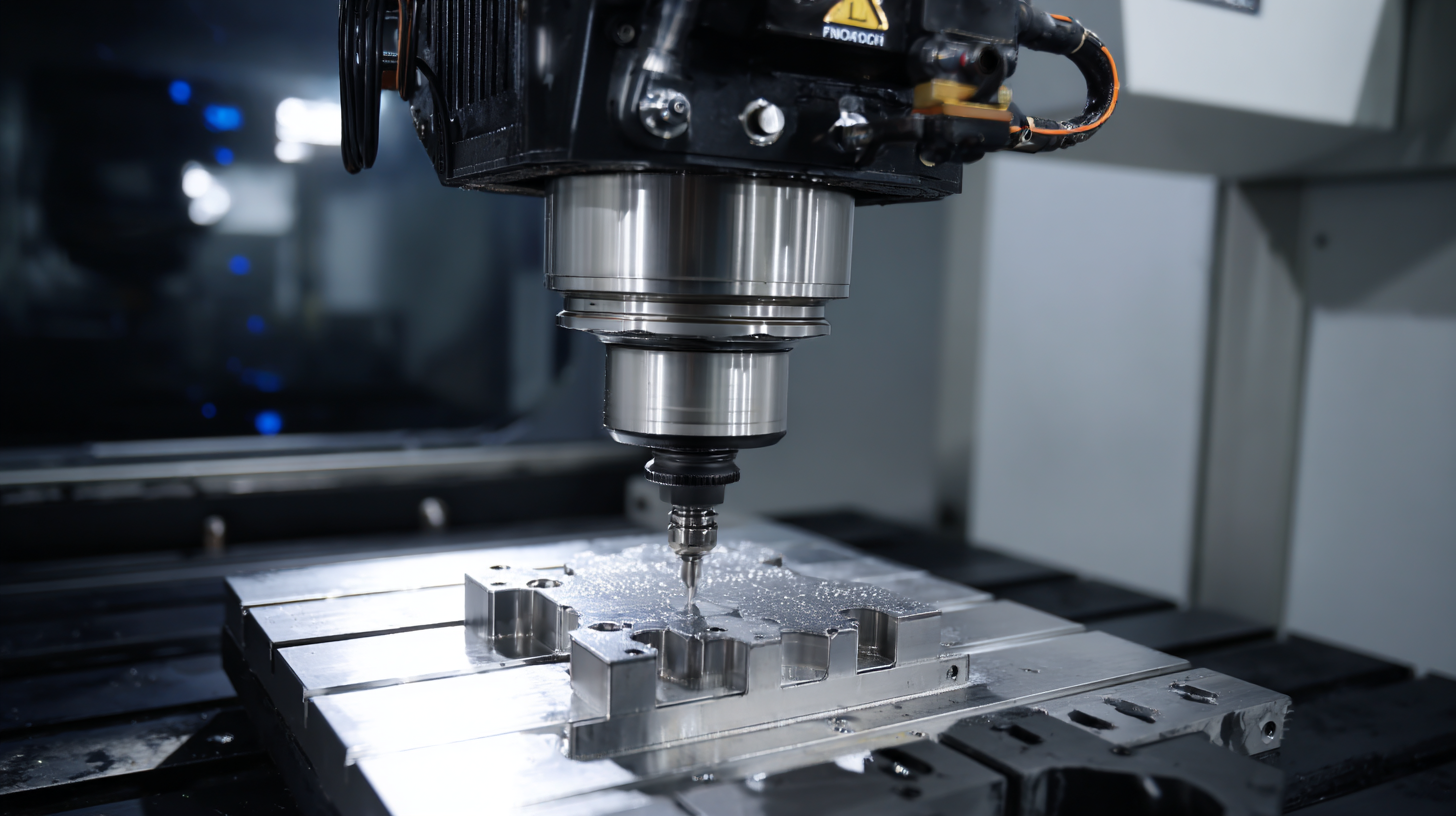

As the manufacturing landscape continues to evolve, the introduction of micro CNC milling machines is emerging as a pivotal innovation in precision engineering. The 2025 China Import and Export Fair serves as a vital platform for showcasing advancements in this technology, which has seen a significant uptick in demand, with global micro CNC milling machine market size projected to reach USD 1.45 billion by 2027, growing at a CAGR of 8.5% (ResearchAndMarkets). This growth is driven by the increasing need for high accuracy and efficiency in manufacturing processes across various industries, from aerospace to medical devices. The compact size and enhanced capabilities of micro CNC milling machines allow manufacturers to produce intricate components with minimal material waste, aligning with sustainability goals. As industry leaders gather for the 138th Canton Fair, the spotlight will be on innovations that exemplify the transformative potential of this technology, redefining manufacturing standards and practices worldwide.

The 2025 Canton Fair is set to showcase the latest advancements in micro CNC milling technology, highlighting its transformative potential in the manufacturing sector. As industries across the globe are becoming increasingly reliant on precision engineering, the emergence of micro CNC milling machines offers manufacturers a powerful tool for enhancing productivity and precision. These compact and efficient machines are designed to execute intricate designs with superior accuracy, making them an essential asset for small to medium-sized enterprises aiming to innovate their production processes.

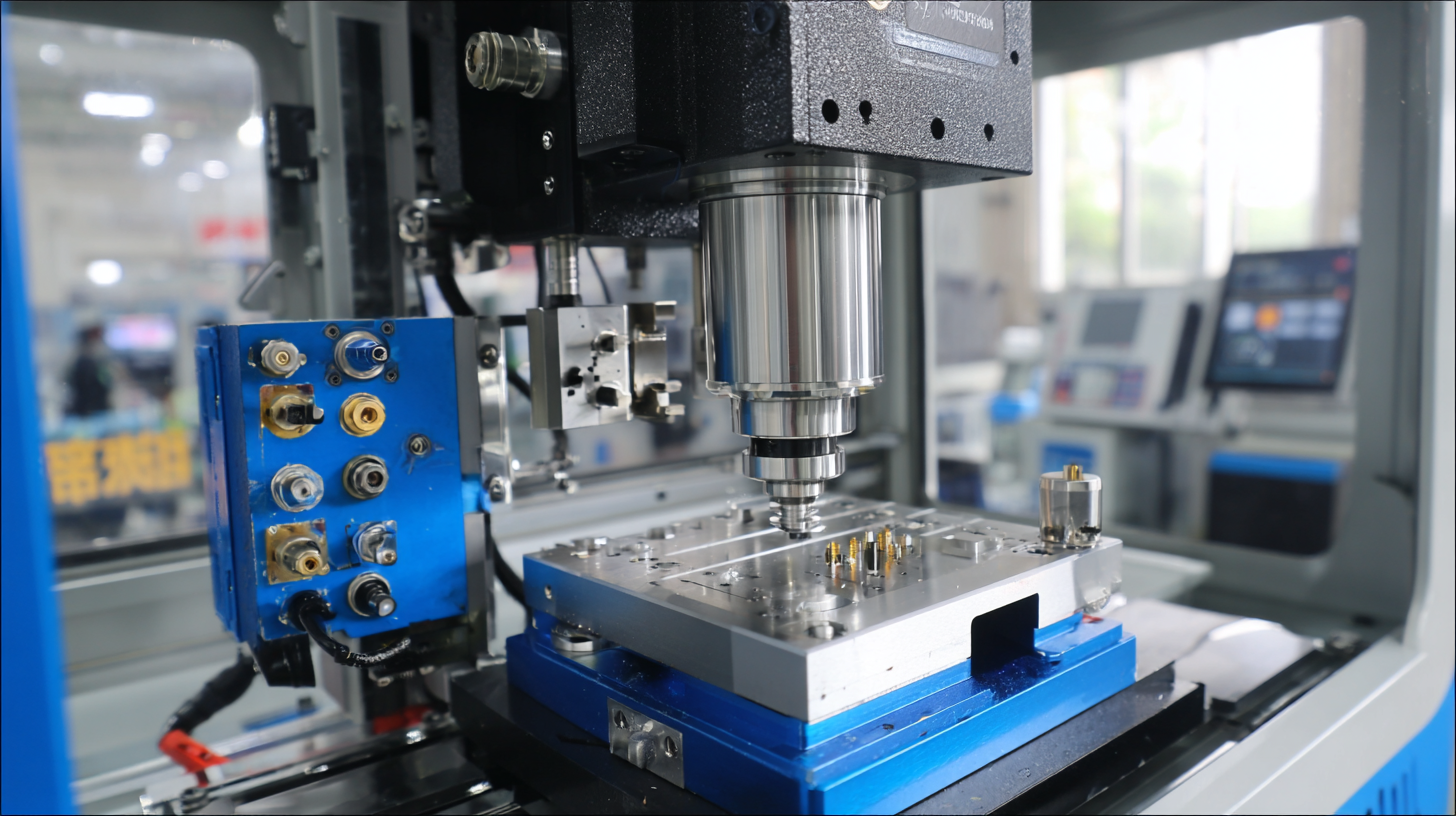

At the fair, attendees can expect to explore cutting-edge innovations that are reshaping the landscape of micro CNC milling. From improved software solutions to advanced control systems, the latest trends indicate a shift towards more automated and user-friendly machines. This evolution not only streamlines operations but also reduces labor costs and minimizes waste. As micro CNC technology continues to advance, it promises to open new avenues for creativity and efficiency in manufacturing, paving the way for a more sustainable and competitive industrial future.

| Feature | Specification | Advantage | Application |

|---|---|---|---|

| Precision Tolerance | ±0.01 mm | High accuracy in machining | Aerospace components |

| Spindle Speed | 30,000 RPM | Enables high-speed machining | Medical device manufacturing |

| Tooling | Interchangeable carbide tools | Versatility in material processing | Custom machinery |

| Control System | CNC with adaptive feedback | Increased efficiency and reduced waste | Electronics assembly |

| Material Compatibility | Metals, plastics, composites | Wide range of applications | Automotive parts |

The impact of micro CNC machines on precision manufacturing industries cannot be overstated, as they play a pivotal role in enhancing accuracy and efficiency. The latest advancements in micro-electrical discharge machining (micro-EDM) address the critical challenges of sustainability and slow material removal rates, paving the way for faster and more eco-friendly manufacturing processes. With the increasing demand for precision components in various sectors, including medical devices, the integration of laser processing alongside CNC milling technologies is yielding remarkable results, enabling the creation of smaller and more complex designs that meet stringent performance requirements.

**Tips**: To optimize your manufacturing processes with micro CNC machines, consider focusing on efficient parametric optimization of machining parameters. Utilizing hybrid methodologies combining statistical tools can significantly enhance the quality and precision of machined components. Moreover, integrating advanced sensors for tool wear detection can improve the longevity and reliability of machining operations, leading to sustainable practices in production.

The evolution of CNC technology, particularly in micro-milling, is set to transform the landscape of precision manufacturing. Techniques such as fluid jet polishing can effectively address the challenges of tool mark removal, ensuring a high-quality finish essential for sensitive applications like micro-fluidic chip molds. Embracing these innovations will not only bolster manufacturing efficiency but also promote a greener approach, aligning with the industry's growing focus on sustainability.

This chart illustrates the growing adoption of Micro CNC milling machines in various precision manufacturing sectors from 2021 to 2025.

Micro CNC milling machines are at the forefront of innovation, showcasing their versatility across diverse sectors at the 2025 China Import and Export Fair. These compact machines offer unparalleled precision, making them ideal for industries such as aerospace, automotive, and medical device manufacturing. For instance, in the aerospace sector, micro CNC milling allows for the production of intricate components that require tight tolerances, enhancing performance and safety. Additionally, the lightweight yet durable parts produced can significantly reduce overall aircraft weight, leading to increased fuel efficiency.

In the medical field, micro CNC milling plays a crucial role in creating custom implants and surgical tools. The ability to work with a variety of materials, including bio-compatible composites, enables manufacturers to tailor products to meet specific patient needs. Furthermore, in the electronics sector, micro CNC technology facilitates the intricate designs of circuit boards and microcomponents, pushing the boundaries of miniaturization and functionality. Overall, the innovative applications of micro CNC milling machines are transforming manufacturing processes, driving efficiency, and pushing technological limits across multiple industries.

As industries strive for greater efficiency and precision, micro CNC milling machines are emerging as groundbreaking tools capable of transforming supply chains. According to a recent report by Grand View Research, the global CNC machine market is expected to reach $117.39 billion by 2025, driven by advancements in technology and increasing demand for precision engineering. These compact yet powerful machines offer manufacturers the ability to produce intricate parts with tight tolerances, thereby reducing waste and cutting down lead times significantly.

The integration of advanced micro CNC capabilities into supply chains is not merely a trend; it is a necessity for maintaining competitiveness in a rapidly evolving market. A study by MarketsandMarkets indicates that the micro machining market is projected to grow at a CAGR of 6.4% from 2020 to 2025. This growth is fueled by the need for custom components in various sectors including aerospace, automotive, and electronics. By adopting micro CNC milling, manufacturers can enhance product customization and achieve just-in-time delivery, ensuring they meet market demands without overcommitting resources. This strategic shift not only streamlines operations but also empowers companies to respond quicker to customer needs, illustrating the profound impact that these innovations have on modern supply chains.

The advent of micro CNC milling machines marks a significant shift in sustainable manufacturing practices, particularly in the context of the 2025 China Import and Export Fair. These compact yet powerful machines allow manufacturers to reduce material waste and energy consumption, aligning perfectly with the global push for more environmentally friendly production methods. By enabling precision cutting and intricate designs, micro CNC milling not only maximizes resource efficiency but also extends the lifecycle of materials used in various industries.

Furthermore, the integration of micro CNC milling technology supports the development of lightweight, high-strength components essential for sustainable engineering. As industries seek to lower their carbon footprints, these machines provide innovative solutions that facilitate recycling and lower production cycles. Their adaptability allows for the implementation of sustainable practices across sectors, proving that efficiency and eco-friendliness can coexist. The 2025 China Import and Export Fair will serve as a pivotal platform to showcase these technologies, fostering a dialogue around their role in shaping the future of manufacturing towards sustainability.