The laser cutting CNC machine is revolutionizing the manufacturing landscape, providing precision and efficiency that traditional methods struggle to match. According to the report from MarketsandMarkets, the global laser cutting market is projected to reach USD 4.56 billion by 2025, growing at a CAGR of 6.6% from 2020. This surge in demand is fueled by the increasing need for high-quality cutting solutions across various industries, from automotive to aerospace. As businesses seek to optimize their production processes, understanding the various types of laser cutting CNC machines available becomes critical.

In this blog, we will explore the ultimate showdown of these machines, analyzing their features, benefits, and potential drawbacks, to help you choose the best option tailored to your unique needs.

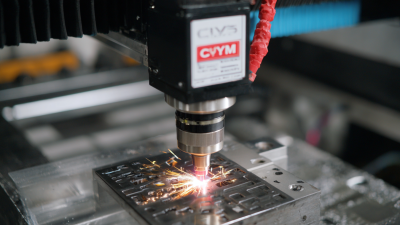

Laser cutting CNC machines have revolutionized manufacturing and design, offering precision and efficiency for a variety of materials. Understanding the basics of these machines is crucial for anyone considering their use. At their core, laser cutting involves directing a high-powered beam of light at a material, effectively melting or vaporizing it to create intricate shapes and designs. This technology can handle metals, plastics, wood, and more, making it a versatile tool in various industries.

When choosing a laser cutting CNC machine, consider the material thickness you intend to work with. Most machines have specific power ratings suited to different thicknesses, which affects cutting speed and quality. Additionally, pay attention to the machine's bed size, as this will determine the maximum size of the projects you can undertake.

Tip: Always check for software compatibility. A user-friendly interface can significantly enhance your experience and productivity.

Tip: Invest in good quality lenses and optics. They play a critical role in focusing the laser beam accurately, thus affecting the cutting performance and quality.

By grasping these fundamentals, you can better navigate the selection process and find a machine that aligns with your specific requirements.

When selecting a laser cutting CNC machine, several key features should be at the forefront of your decision-making process. First and foremost, power output is crucial, as it directly influences the types of materials you can cut and the thickness of those materials. A machine with higher wattage can handle tougher materials like stainless steel and thick acrylic, making it a versatile choice for various applications. Additionally, consider the speed and precision of the cutting process. Machines that offer higher cutting speeds and tighter tolerances are essential for achieving intricate designs and reducing production time.

Another important feature to compare is the size of the cutting bed. Depending on your projects, a larger cutting area may be necessary for accommodating bigger materials without the need for manual repositioning. Furthermore, the software compatibility and ease of use are critical elements for streamlining your workflow. Look for machines that come with intuitive software that can easily integrate with your existing design tools. By focusing on these key features, you can ensure that you select a laser cutting CNC machine that best suits your specific needs and production requirements.

When selecting a laser cutting CNC machine, it's important to compare key features such as cutting speed, precision, and maximum material thickness. The chart below presents a comparison of these features across different laser cutting CNC machines.

In the realm of manufacturing, the selection of laser cutting technology can significantly impact production efficiency and product quality. There are three primary types of laser cutting technologies: CO2 lasers, fiber lasers, and solid-state lasers. According to a recent report by Allied Market Research, the global laser cutting machine market is projected to reach $6.9 billion by 2025, with fiber lasers expected to hold a dominant share due to their high performance and versatility. These machines are renowned for cutting metals with exceptional speed and precision, making them ideal for industries such as automotive and aerospace.

In the realm of manufacturing, the selection of laser cutting technology can significantly impact production efficiency and product quality. There are three primary types of laser cutting technologies: CO2 lasers, fiber lasers, and solid-state lasers. According to a recent report by Allied Market Research, the global laser cutting machine market is projected to reach $6.9 billion by 2025, with fiber lasers expected to hold a dominant share due to their high performance and versatility. These machines are renowned for cutting metals with exceptional speed and precision, making them ideal for industries such as automotive and aerospace.

CO2 lasers, on the other hand, excel in cutting non-metal materials like plastics, wood, and glass, making them a favorite in the signage and packaging sectors. A study from MarketsandMarkets indicates that the demand for CO2 laser technology is also on the rise, driven by its cost-effectiveness and ability to handle large sheets. Understanding the unique strengths of each laser cutting technology can help businesses make informed decisions that align with their operational needs and material requirements, ultimately enhancing productivity and reducing costs.

When embarking on the journey of selecting a laser cutting CNC machine, it's essential to first assess your project needs. Start by defining your budget, as it will significantly determine the options available to you. High-end machines offer advanced features and capabilities but can be a substantial investment. Establishing a clear budget will help narrow down your search to models that not only fit your financial parameters but also meet the performance requirements of your projects.

Next, consider the volume of work you plan to undertake. If your projects require high throughput, you'll need a machine that can handle large quantities without sacrificing precision. On the other hand, if your focus is on smaller, intricate designs, a machine with fine cutting capabilities might be more suitable. Additionally, examine the materials you will work with—different machines are compatible with various materials, from wood and metal to plastics and textiles. Ensuring that the CNC machine can effectively handle your specific materials is crucial for achieving the desired results and optimizing your production workflow.

When choosing a laser cutting CNC machine, it's essential to consider the top brands and models currently available in the market. Renowned names like Epilog, Trotec, and Universal Laser Systems have established themselves through cutting-edge technology and reliability. Each offers a range of products tailored to different needs, from small businesses to large-scale industrial applications. Epilog's Fusion Pro series, for example, is noted for its speed and precision, making it a favorite among artisans and manufacturers alike.

Tips: When evaluating CNC machines, pay attention to the machine's wattage, as higher power typically results in faster cutting speeds and the ability to work with thicker materials. Also, consider the machine's software compatibility, as user-friendly design software can significantly enhance productivity and ease of use.

Additionally, keep an eye on customer support and warranty options provided by manufacturers. A solid warranty can protect your investment, while responsive customer service is invaluable for troubleshooting and maintenance. Checking user reviews or forums can offer insights into the real-world performance of various models, guiding you to make an informed choice based on your specific requirements.

| Model | Laser Type | Max Cutting Area (mm) | Laser Power (W) | Engraving Speed (mm/s) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | CO2 | 1200 x 800 | 150 | 800 | $3,000 - $4,500 |

| Model B | Fiber | 1500 x 1000 | 200 | 1200 | $4,500 - $7,000 |

| Model C | Fiber | 1000 x 600 | 100 | 600 | $2,500 - $3,500 |

| Model D | CO2 | 1300 x 900 | 150 | 700 | $3,200 - $4,000 |

| Model E | CO2 | 1600 x 1000 | 300 | 1000 | $5,000 - $8,000 |