In the realm of precision manufacturing, the role of an industrial CNC milling machine cannot be overstated. These versatile tools form the backbone of numerous industries, enabling manufacturers to produce intricate parts and components with unparalleled accuracy. From aerospace to automotive, the demand for high-quality precision parts continues to rise, and industrial CNC milling machines are at the forefront of meeting this need. Their ability to automate complex machining processes not only enhances productivity but also minimizes human error, making them indispensable in modern manufacturing settings.

As we delve into the top 10 industrial CNC milling machines, it is essential to understand the advancements that have shaped these powerful machines. Over the years, technology has evolved, leading to enhanced features such as multi-axis capabilities, advanced coolant systems, and sophisticated software integration. These innovations allow for greater efficiency, flexibility, and precision, supporting manufacturers in tackling increasingly complex projects. The machines highlighted in this guide represent the pinnacle of engineering and design, embodying the cutting-edge developments that have defined the industry. Whether you are looking to upgrade your existing equipment or invest in new machinery, understanding the key features and advantages of the best industrial CNC milling machines will be crucial in driving your production capabilities forward.

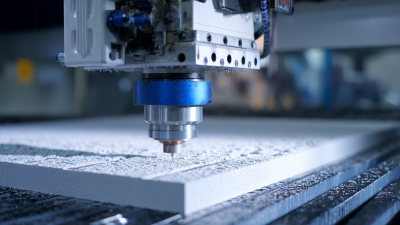

CNC milling machines play a critical role in precision manufacturing, offering unparalleled accuracy and efficiency in the production process. By leveraging computer numerical control technology, these machines can operate with a degree of precision that manual milling cannot achieve. This capability is essential for industries that require tight tolerances and complex geometries, such as aerospace, automotive, and medical device manufacturing. The automation provided by CNC milling not only enhances productivity but also reduces the likelihood of human error, ensuring consistent results across large production runs.

In addition to their precision, CNC milling machines are versatile tools that can handle a diverse range of materials, including metals, plastics, and composites. This adaptability makes them an integral part of modern manufacturing strategies. Programmable settings allow for easy reconfiguration, enabling manufacturers to switch between different projects without significant downtime. Furthermore, advancements in software and machine design have led to improvements in speed and operational efficiency, empowering manufacturers to meet the demands of a rapidly changing marketplace while maintaining high-quality standards.

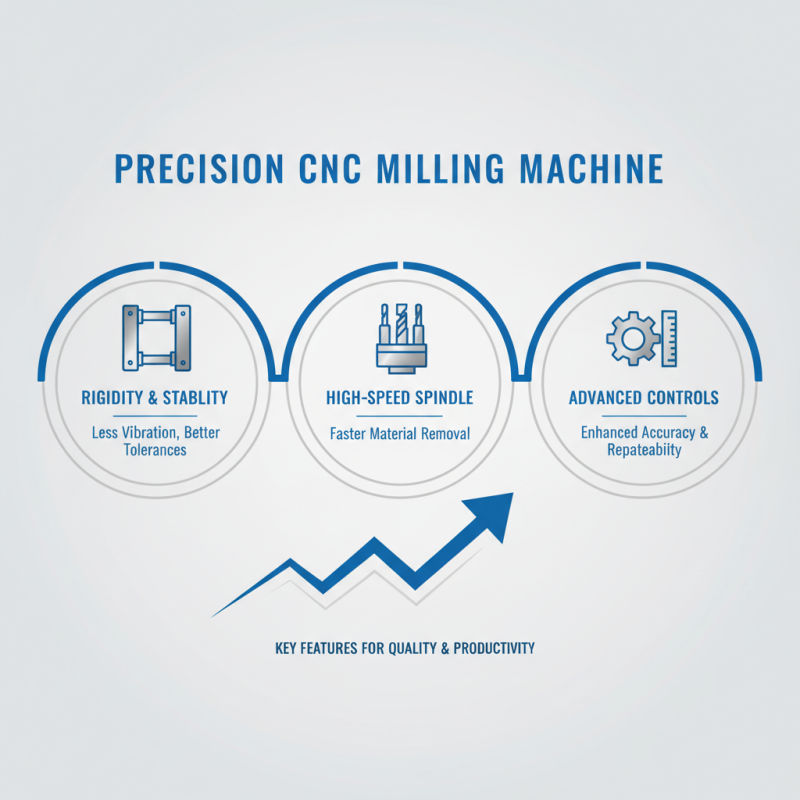

When selecting a CNC milling machine for precision manufacturing, several key features can significantly influence productivity and quality. Firstly, the machine's rigidity and stability are paramount. According to a report by the Association for Manufacturing Technology (AMT), increased rigidity results in less vibration and better tolerances. High-quality machines often incorporate robust materials and designs that enhance their stiffness, thereby ensuring consistent cutting performance and extended tool life.

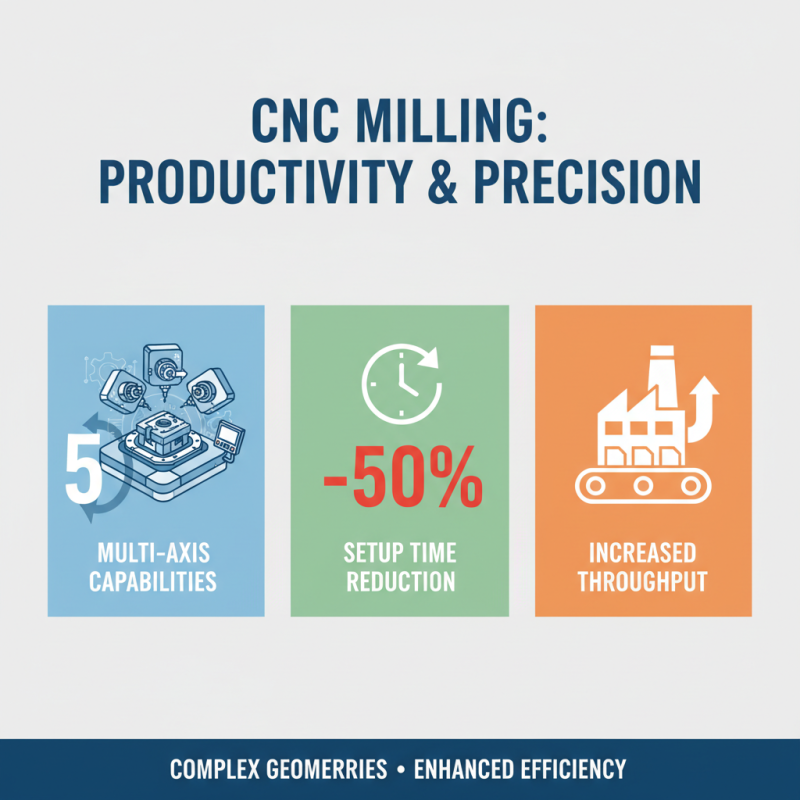

Another critical aspect is the CNC control system's sophistication. An advanced control system can facilitate complex programming, thereby enabling the production of intricate designs with greater accuracy. According to the International Journal of Advanced Manufacturing Technology, machines equipped with modern CNC software can reduce programming time by up to 50%, allowing manufacturers to respond more swiftly to market changes. Additionally, features like automated tool changers and high spindle speeds can significantly enhance operational efficiency, reducing downtime and increasing throughput.

Lastly, the machine's capability for handling various materials can broaden its application range. Data from the Manufacturing Institute indicates that machines capable of milling both metals and composites cater to a wider market, making them more versatile in an evolving manufacturing landscape. By prioritizing these features, manufacturers can ensure they choose CNC milling machines that meet the demands of precision production.

In the realm of precision manufacturing, CNC milling machines play a pivotal role in enhancing productivity and accuracy. The top models in this category are distinguished by their impressive specifications and unique features that cater to various industrial needs. For instance, many contemporary CNC milling machines boast multi-axis capabilities, allowing for complex geometries and improved machining efficiency. Reports indicate that machines equipped with five-axis technology can reduce setup times by up to 50%, thereby significantly increasing throughput in production environments.

When considering a CNC milling machine, it’s essential to pay attention to the spindle speed and torque. High-speed spindles, typically rated at 15,000 RPM or higher, enable faster material removal rates, while sufficient torque ensures optimal performance across different cutting operations. Additionally, advanced cooling systems and tool changers can drastically minimize downtime, with some systems allowing tool changes in under five seconds. These innovative features enhance not only the precision but also the lifespan of the machinery, reducing overall operational costs.

Tips: When selecting a CNC milling machine, consider the specific materials you plan to work with. Different machines handle materials like aluminum, steel, or titanium more effectively based on their design and technology. Furthermore, investing in training for operators can yield significant returns by maximizing the effectiveness and longevity of your CNC equipment.

CNC milling machines have become indispensable tools across various industries due to their precision and versatility. In manufacturing, these machines facilitate the production of complex components with tight tolerances. For instance, in the automotive sector, CNC milling is used to create parts such as engine blocks and transmission housings, where accuracy is critical to performance and safety. The aerospace industry also relies heavily on CNC milling to manufacture lightweight, high-strength components, ensuring compliance with stringent safety standards while optimizing fuel efficiency.

In the medical field, CNC milling helps produce precise instruments and implants tailored to individual patient needs, enhancing surgical outcomes. Similarly, in the electronics industry, these machines are utilized for fabricating complex circuit boards and housings for electronic devices, where minute details can significantly impact functionality.

Tips: When selecting a CNC milling machine, consider factors such as the material you will be working with, the required precision, and the size of the components. Additionally, invest in proper training for your operators to maximize efficiency and maintain the accuracy of the machines. Regular maintenance is crucial to ensure consistent performance and extend the lifespan of the equipment.

The landscape of CNC milling technology is evolving rapidly, driven by advancements in automation, artificial intelligence, and data analytics. One major trend is the increasing integration of smart technologies and IoT (Internet of Things) capabilities within milling machines. This connectivity allows for real-time monitoring and data collection, enabling manufacturers to optimize processes, predict maintenance needs, and improve overall machine efficiency. As machines become smarter, they also enhance precision, significantly reducing downtime and production costs while increasing output quality.

Another significant trend is the ongoing development of advanced materials and cutting tools that can withstand higher speeds and pressures. These innovations not only extend the lifespan of milling tools but also allow for greater precision in the manufacturing of complex components. Additionally, as industries push for sustainability, manufacturers are increasingly focusing on eco-friendly practices, such as reduced energy consumption and the use of recyclable materials. This commitment to sustainability aligns with the growing demand for environmentally responsible manufacturing processes, making future CNC milling machines not only more capable but also more conscientious.